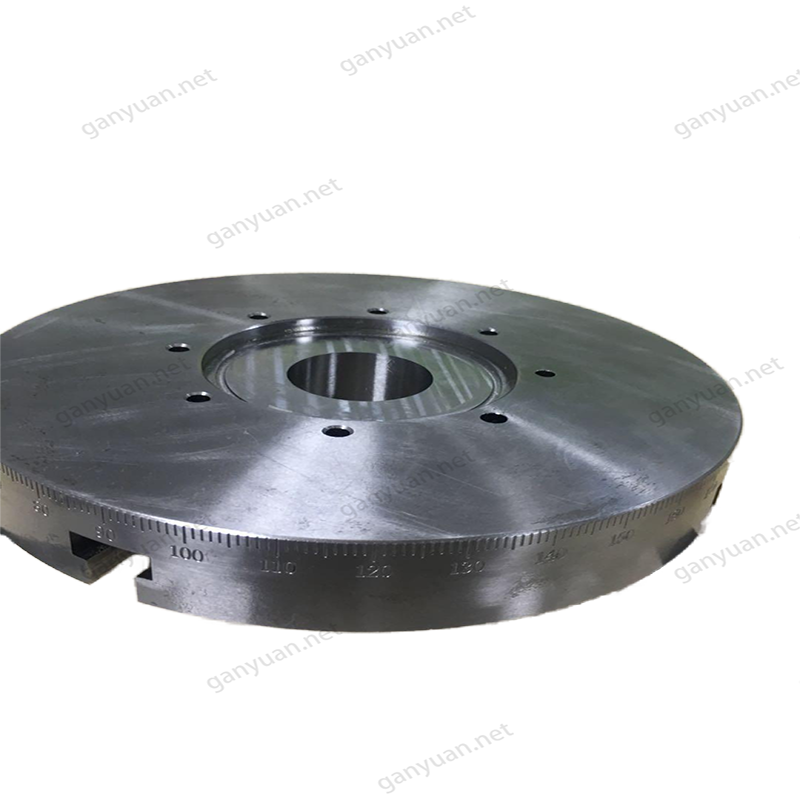

Trustworthy Precision 4-axis Machinery Parts Stainless Steel Flange Dial Engraving Dial Support Custom Factory China

enquiry- Specifications

Our Stainless Steel Flange Dial is a high-precision measurement component manufactured from grade 304/316 stainless steel through advanced CNC turning and milling processes. Designed for industrial instrumentation and control systems, it delivers exceptional corrosion resistance and long-term dimensional stability.Stainless Steel Flange Dial

Technical Specifications

| Feature | Specification |

|---|---|

| Material | 304/316 Stainless Steel (ASTM A276 compliant) |

| Manufacturing Process | CNC Turning + Precision Milling Stainless Steel Flange Dial |

| Tolerance | ±0.01mm (critical surfaces) |

| Surface Finish | Ra 0.4μm (mirror polish optional) |

| Flange Types | Slip-on, Weld Neck, Threaded (customizable) |

| Diameter Range | 20mm–300mm (standard) |

| Marking Options | Laser engraving, etched graduations |

Stainless Steel Flange Dial Key Advantages

✔ Ultra-Precise Machining

-

4-axis CNC milling ensures perfect concentricity

-

Micro-graduation engraving with ≤0.05° angular accuracy

✔ Premium Material Properties

-

316L variant available for marine/chemical environments

-

Passivation treatment standard on all units Stainless Steel Flange Dial

✔ Customization Ready

-

Custom bore sizes and bolt circle patterns

-

Optional luminescent markings for low-light visibility

✔ Rigorous Quality Control

-

100% CMM inspection for flatness and runout

-

Salt spray tested per ASTM B117 (500+ hours)

Stainless Steel Flange Dial Manufacturing Process

-

Material Preparation

-

Precision saw cutting of stainless steel billets

-

Stress-relief annealing when required

-

CNC Machining

-

Turning: Achieves IT6 grade dimensional accuracy

-

Milling: 4-axis contouring for complex flange features

-

Surface Enhancement

-

Electrolytic polishing for Ra 0.2μm super-finish

-

Bead blasting for matte aesthetic (upon request)

-

Final Verification

-

Laser scanning for profile verification

-

Torque testing on threaded variants

Why Partner With Us?

-

20+ Years of precision Stainless Steel Flange Dial manufacturing

-

ISO 9001:2015 certified production

-

DFM Support for custom requirements

-

Fast-Turn Prototyping (5-7 working days)

If you are interested in our products, please contact me and I will provide the best price support and quality service.Stainless Steel Flange Dial

I believe we will establish a good and long-term cooperation.Stainless Steel Flange Dial

Welcome to send pictures and letters to discuss, thank you!

Surface Treatment Options

-

Hard anodizing (up to 50μm)

-

Electroless nickel plating

-

Passivation for stainless steel

-

Bead blasting for uniform matte finish

-

PVD coatings for wear resistance

Packaging & Service

-

Premium Packaging: Anti-static bags + Foam protection + Gift box options

-

OEM/ODM Services: Provide samples or drawings (PDF/STEP/IGS formats accepted)

-

Global Shipping: DHL/FedEx/Sea freight supported

FAQ

✓ Custom design consultations

✓ Sample requests

✓ Volume production quotes