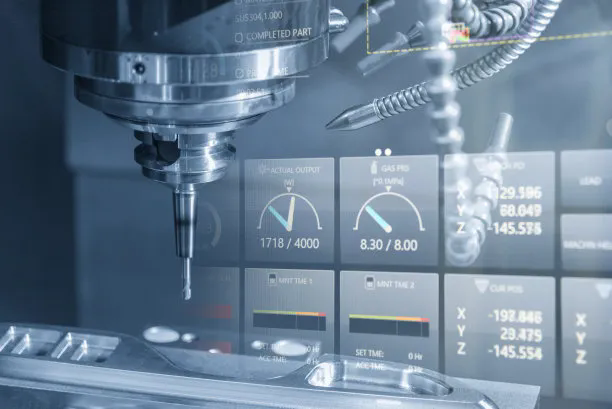

Trustworthy Custom High precision 304 stainless steel parts CNC turning and milling combined machining

enquiry- Specifications

304 stainless steel is one of the most widely used austenitic stainless steels, renowned for its exceptional corrosion resistance, durability, and versatility. Composed of 18% chromium and 8% nickel, this material is ideal for various industrial, commercial, and household applications. Its excellent mechanical properties, weldability, and formability make it a preferred choice for manufacturers worldwide.

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,cnc machined components |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;304 stainless steel |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Key Properties of 304 Stainless Steel

1. Superior Corrosion Resistance

304 stainless steel excels in resisting oxidation and corrosion in various environments, including exposure to moisture, acids, and chemicals. The high chromium content forms a passive oxide layer that protects the material from rust and degradation, making it perfect for:

-

Food processing equipment

-

Kitchen appliances (sinks, cookware, cutlery)

-

Medical instruments

-

Marine and architectural applications

2. High Strength and Durability

With excellent tensile strength and toughness, 304 stainless steel withstands extreme temperatures and mechanical stress. Its durability ensures long-lasting performance in demanding industries such as:

-

Automotive components (exhaust systems, fuel tanks)

-

Industrial machinery

-

Chemical storage tanks

3. Excellent Formability and Weldability

304 stainless steel is highly malleable, allowing for easy fabrication into complex shapes. It can be:

-

Deep drawn (for sinks and cookware)

-

Machined (CNC milling, turning)

-

Welded (TIG, MIG, and spot welding) without losing structural integrity

4. Hygienic and Easy to Maintain

Its non-porous surface prevents bacterial growth, making it ideal for:

-

Medical and pharmaceutical equipment

-

Food and beverage processing

-

Sanitary fittings

Applications of 304 Stainless Steel

1. Automotive Industry

Our precision CNC milling services utilize 304 stainless steel to manufacture high-performance automotive parts, including:

-

Engine components (crankshafts, cylinder blocks)

-

Transmission gear sets

-

Exhaust systems

-

Structural body parts

With tolerances as tight as ±0.02mm, we ensure perfect fit and optimal performance.

2. Industrial and Manufacturing Equipment

304 stainless steel is used in:

-

Piping systems

-

Valves and pumps

-

Heat exchangers

-

Conveyor systems

3. Household and Consumer Goods

From kitchen essentials to decorative items, 304 stainless steel enhances durability and aesthetics in:

-

Sinks, faucets, and countertops

-

Appliances (refrigerators, ovens)

-

Furniture and architectural trim

Why Choose Our 304 Stainless Steel Solutions?

1. Advanced Manufacturing Capabilities

Our factory in Dongguan, China, is equipped with:

-

CNC lathes, 5-axis & 4-axis CNC machines

-

Stamping & die-casting equipment

-

Surface treatment facilities (electroplating, anodizing, polishing)

2. Strict Quality Control

We ensure top-tier quality through:

-

3D & 2D precision testing

-

Hardness and dimensional inspections

-

Material certifications (ISO standards)

3. Customization & Fast Delivery

-

Minimum order quantity: 10 pieces

-

Lead time: 15 days

-

Custom surface treatments (polishing, coating, plating)

Competitive Advantages in Stainless Steel Vibrating Discs

✅ Tolerances as tight as ±0.02mm

✅ Fast prototyping & low MOQ (10 pieces)

✅ One-stop machining & finishing services

✅ Strict quality assurance with full traceability

✅ Competitive pricing & on-time delivery

FAQ

Partner With Us

"Your design vision, our engineering precision – let's create something extraordinary."

Request a Free Project Review

📧 Email: ganyuan1688@gmail.com

🌐 Website: ganyuan1688@gmail.com

📞 Tel: 86--13929256361

Dongguan Ganyuan Hardware Technology Co., Ltd.

📩 Send your drawings (PDF/STEP/IGS) for instant pricing

📞 Discuss your project with our engineering team