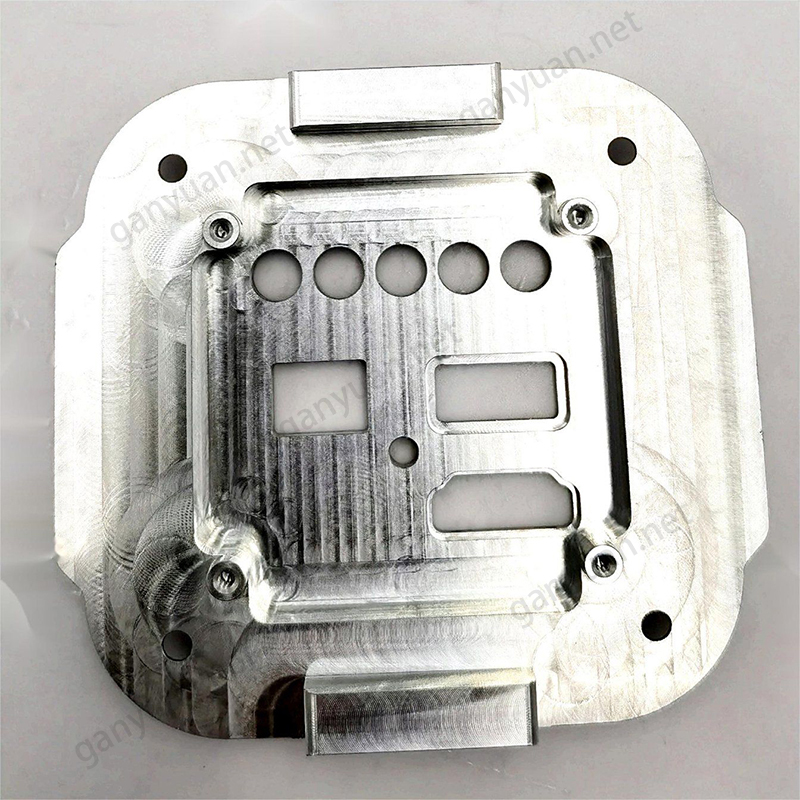

Trustworthy precision turned parts Custom 5 Axis CNC Machining CNC Lathe Machining Aluminum

enquiry- Specifications

At Dongguan Ganyuan Hardware Technology Co., Ltd., we are dedicated to producing precision turned parts that set new standards in accuracy, quality, and performance. With over 20 years of industry expertise, we combine skilled craftsmanship with state-of-the-art CNC technology to deliver components that enhance your production efficiency.

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;precision turned parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Why Choose Our Precision Turned Parts?

When it comes to high-precision turning parts, we stand out for our commitment to excellence. Our customized CNC precision machined parts are engineered to meet the most demanding specifications, ensuring seamless integration into your applications.

Unmatched Accuracy in Precision Turned Parts

Our advanced CNC lathes and multi-axis machining centers guarantee micron-level tolerances, making our precision turned parts ideal for industries where exact measurements are critical. Whether for automotive, aerospace, medical, or industrial applications, we ensure consistent quality in every batch.

Advanced Manufacturing Capabilities for Precision Turned Parts

To meet diverse production needs, we utilize:

✔ 5-Axis & 4-Axis CNC Machining – Capable of handling complex geometries with high efficiency.

✔ High-End Turning Equipment – Delivering flawless finishes for both micro and large-scale components.

✔ Comprehensive Surface Treatments – Including anodizing, plating, and polishing for enhanced durability.

Material Versatility for Precision Turned Parts

We work with a broad range of materials to suit various industry requirements:

-

Aluminum Alloys (6061, 7075) – Lightweight yet strong for high-performance applications.

-

Stainless Steel (303, 304, 316) – Perfect for corrosive environments.

-

Brass, Copper, Titanium, and Engineering Plastics – Customized for electrical, medical, and mechanical uses.

Rigorous Quality Control for Precision Turned Parts

Every precision turned part undergoes strict inspection using:

✔ 3D & 2D Measuring Systems – Ensuring dimensional accuracy.

✔ Hardness Testers & Projectors – Verifying material integrity.

✔ Surface Finish Analysis – Guaranteeing smooth, defect-free components.

Custom Precision Turned Parts for Your Unique Needs

We specialize in custom precision turning, offering:

✔ Prototyping & Mass Production – Fast turnaround without compromising quality.

✔ Tight Tolerance Machining (±0.005mm) – Ideal for critical applications.

✔ Complete Finishing Services – Including electroplating, anodizing, and sandblasting.

Industries We Serve with Precision Turned Parts

Our precision turned parts are trusted across multiple sectors:

✔ Automotive – Engine components, sensors, and transmission parts.

✔ Aerospace – High-strength, lightweight fittings.

✔ Medical – Surgical instruments and implant-grade parts.

✔ Electronics – Connectors, housings, and heat sinks.

Seamless Ordering Process for Precision Turned Parts

Simply send your PDF/DWG/STP/IGS drawings, and our team will provide:

✅ Fast Quotation – Competitive pricing with transparent costs.

✅ DFM Feedback – Expert design optimization suggestions.

✅ Reliable Delivery – On-time shipments with secure packaging.

Why Partner with Us for Precision Turned Parts?

✔ 20+ Years of Machining Expertise – Proven track record in precision manufacturing.

✔ 2,000㎡ Facility with Advanced CNC Technology – Ensuring high-quality production.

✔ ISO-Compliant Quality Assurance – Meeting international standards.

✔ End-to-End Customization Support – From design to final delivery.

FAQ

Partner With Us

"Your design vision, our engineering precision – let's create something extraordinary."

Request a Free Project Review

📧 Email: ganyuan1688@gmail.com

🌐 Website: ganyuan1688@gmail.com

📞 Tel: 86--13929256361

Dongguan Ganyuan Hardware Technology Co., Ltd.

📩 Send your drawings (PDF/STEP/IGS) for instant pricing

📞 Discuss your project with our engineering team