Efficient Custom production CNC Machining CNC Lathe Machining 5 Axis CNC Machining

enquiry- Specifications

In today's competitive manufacturing landscape, custom production has become a game-changer. It allows businesses to obtain products that are precisely engineered to their specifications, ensuring optimal performance, efficiency, and durability. At Dongguan Ganyuan Hardware Technology Co., Ltd., we specialize in high-precision CNC machining parts, offering five-axis and four-axis machining solutions that redefine accuracy and reliability.Custom production

Product Description Custom production

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | cnc precision parts 5-axis CNC machining center, grinder, Custom production |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;Custom production |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Our custom production process ensures that every component meets the highest standards, whether for aerospace, automotive, medical, or industrial applications. By leveraging advanced CNC technology, we deliver superior surface finishes, tight tolerances, and exceptional durability—all tailored to your exact requirements.Custom production

How We Ensure Precision in Custom Production

1. Strict Drawing Review & Customer Collaboration

Before production begins, our engineering team meticulously reviews CAD files and technical drawings to confirm every dimension, tolerance, and surface finish requirement. If any discrepancies arise, we engage in real-time communication with clients to ensure clarity and precision.

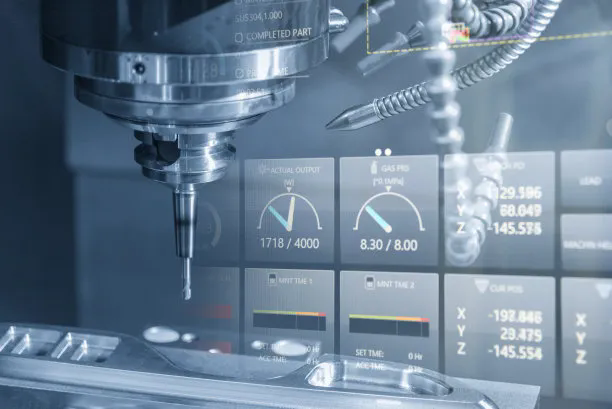

2. Advanced CNC Machining Technology

We utilize high-end CNC lathes, 5-axis, and 4-axis machining centers to achieve micron-level accuracy. Our machines feature high-precision spindles and servo-driven feed systems, allowing us to control cutting depth, speed, and feed rates with exceptional precision.

3. Rigorous Quality Control & Inspection

-

Precision Measuring Tools: Micrometers, calipers, and CMM (Coordinate Measuring Machines) verify dimensional accuracy.

-

Surface Roughness Testers: Ensure optimal finish quality per customer specifications.

-

In-Process Inspections: Continuous checks at every production stage prevent defects.

4. Optimized Surface Treatments

Depending on application needs, we apply:

-

Polishing & Sandblasting for smooth finishes.

-

Anodizing, Plating, or Heat Treatment for enhanced durability.

-

Laser Marking & Passivation for corrosion resistance.

5. Material Excellence

We source premium-grade materials, including:

-

Stainless Steel (303/304/316)

-

Aluminum Alloys (6061, 7075)

-

Titanium, Brass, Copper, and Engineering Plastics (PEEK, Nylon, etc.)

Why Choose Our Custom Production Services?

✔ 20+ Years of CNC Machining Expertise

✔ 2,000+㎡ Advanced Manufacturing Facility

✔ ISO-Compliant Quality Management

✔ Fast Turnaround & Competitive Pricing

✔ End-to-End Support from Prototyping to Mass Production

Applications of Our Custom CNC Parts

Our precision-machined components are widely used in:

-

Aerospace: High-strength, lightweight parts for aircraft systems.

-

Automotive: Engine components, transmission parts, and custom fittings.

-

Medical: Surgical instruments, implants, and diagnostic equipment.

-

Industrial Machinery: High-wear resistance parts for automation systems.

Experience the Power of Custom Production

At Dongguan Ganyuan Hardware Technology Co., Ltd., we don’t just manufacture parts—we engineer perfection. Whether you need prototypes, small batches, or large-scale production, our custom CNC machining solutions ensure unmatched precision, durability, and performance.

Packing&Shipping

FAQ

Request Your Custom Quote Today!

📧 Email: ganyuan1688@gmail.com

🌐 Website: ganyuan1688@gmail.com

📞 Tel: 86–13929256361

Why Choose Us?

→ Precision CNC Milling Parts (±0.02mm)

→ Fast Turnaround (10-15 Days)

→ Medical, Automotive & Aerospace Expertise

→ Competitive Pricing & Quality Guarantee

Upgrade Your Manufacturing with Our Precision Components! 🚀