Precise and efficient! Expert ratchet processing in custom 5 axis CNC

enquiry- Specifications

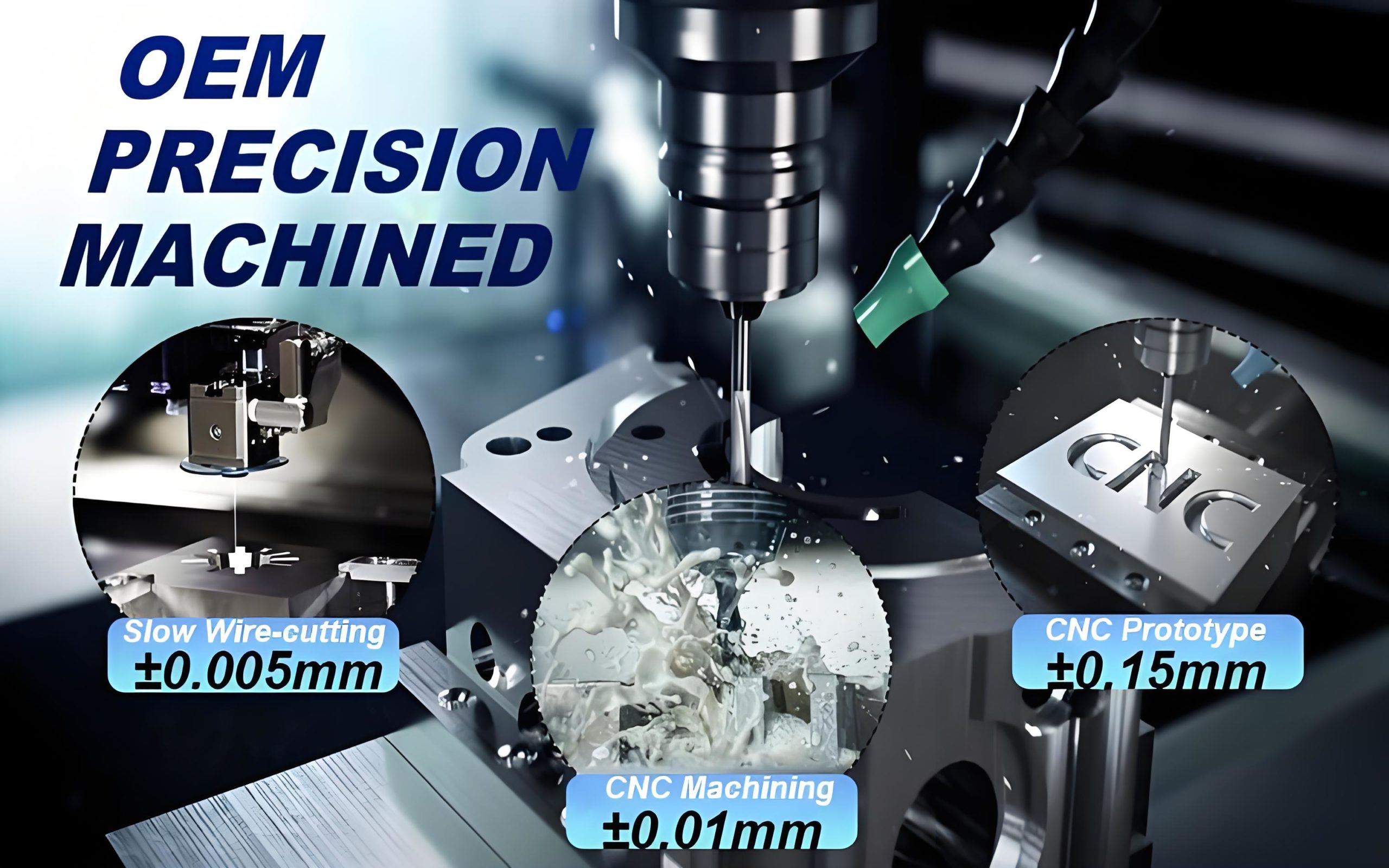

Dongguan Ganyuan Hardware Technology Co., ratchet processing Ltd. proudly presents our superior CNC Parts for Five-Axis Machining. Our precision-engineered CNC Machining Parts are the epitome of quality and efficiency, tailored for high-performance milling machines. Elevate your machinery with our meticulously crafted CNC Machining Components, designed to meet the highest standards of accuracy and durability.

Whether you choose our state-of-the-art Five-Axis or versatile Four-Axis CNC Machining Parts, you will significantly optimize your production processes. Rely on our CNC Machined Parts for unparalleled reliability and consistent performance. Revitalize your machining system with our premium CNC Parts, specifically designed for Five-Axis Machines, ensuring excellence in every cut. ratchet processing

Product Description

Advanced Ratchet Processing Techniques

Precise and efficient! Expert in custom 5 axis CNC ratchet processing ratchet processing

Ratchet processing involves high-precision manufacturing to ensure durability, smooth operation, and reliable performance. Our factory specializes in producing ratchets using advanced CNC machining and multi-axis milling technologies, guaranteeing exceptional accuracy and surface finish.ratchet processing

CNC Lathe Processing for Ratchets

The initial stage of ratchet processing involves CNC lathe operations, which include:

-

Rough Machining: Removing excess material to form the basic shape.

-

Precision Turning: Finishing the outer diameter and end faces to meet tight tolerances.

-

High-Speed Cutting: Ensuring smooth surfaces and precise dimensions.

CNC lathes provide high efficiency and repeatability, making them ideal for producing consistent ratchet components.ratchet processing

Four-Axis CNC Milling for Complex Geometries

After lathe processing, the ratchet undergoes four-axis CNC milling to achieve intricate features such as:

-

Gear Teeth & Pawl Engagement Surfaces: Precision-cut for smooth ratcheting action.

-

Internal Splines & Keyways: Machined with high accuracy for secure fitting.

-

Contoured Handles & Ergonomic Designs: Enhanced for user comfort and functionality.

Four-axis CNC machining ensures complex shapes are produced with tight tolerances and superior surface quality.ratchet processing

Quality Control & Surface Treatment

To guarantee performance and longevity, each ratchet undergoes rigorous inspection and finishing processes:

-

Dimensional Verification: Using CMM (Coordinate Measuring Machine), height gauges, and optical projectors.

-

Surface Hardening: Heat treatment for enhanced wear resistance.

-

Protective Coatings: Options include nickel plating, black oxide, anodizing, or powder coating.

Our Manufacturing Capabilities

Located in Dongguan, China, our facility spans 2,000+ sqm and is equipped with:

-

High-Precision CNC Lathes & Multi-Axis Machining Centers

-

Stamping & Die-Casting Equipment

-

Advanced Surface Treatment Facilities

Material Options for Ratchet Manufacturing

We work with premium materials, including:

-

Steel Alloys (1045, 4140, 4340)

-

Stainless Steel (303, 304, 316)

-

Aluminum (6061, 7075)

-

Brass & Titanium Alloys

Custom Surface Finishing Services

-

Hardening & Tempering

-

Electroplating (Nickel, Zinc, Chrome)

-

Anodizing & Powder Coating

-

Laser Marking for Branding

Why Choose Us for Ratchet Processing?

✅ 20+ Years of Precision Manufacturing Experience

✅ Strict Quality Control with ISO-Compliant Testing

✅ Competitive Pricing & Fast Turnaround

✅ Custom Solutions for OEM/ODM Projects