Professional Metal processing of high-precision and durable 5 axes CNC lathe parts

May 20, 2025

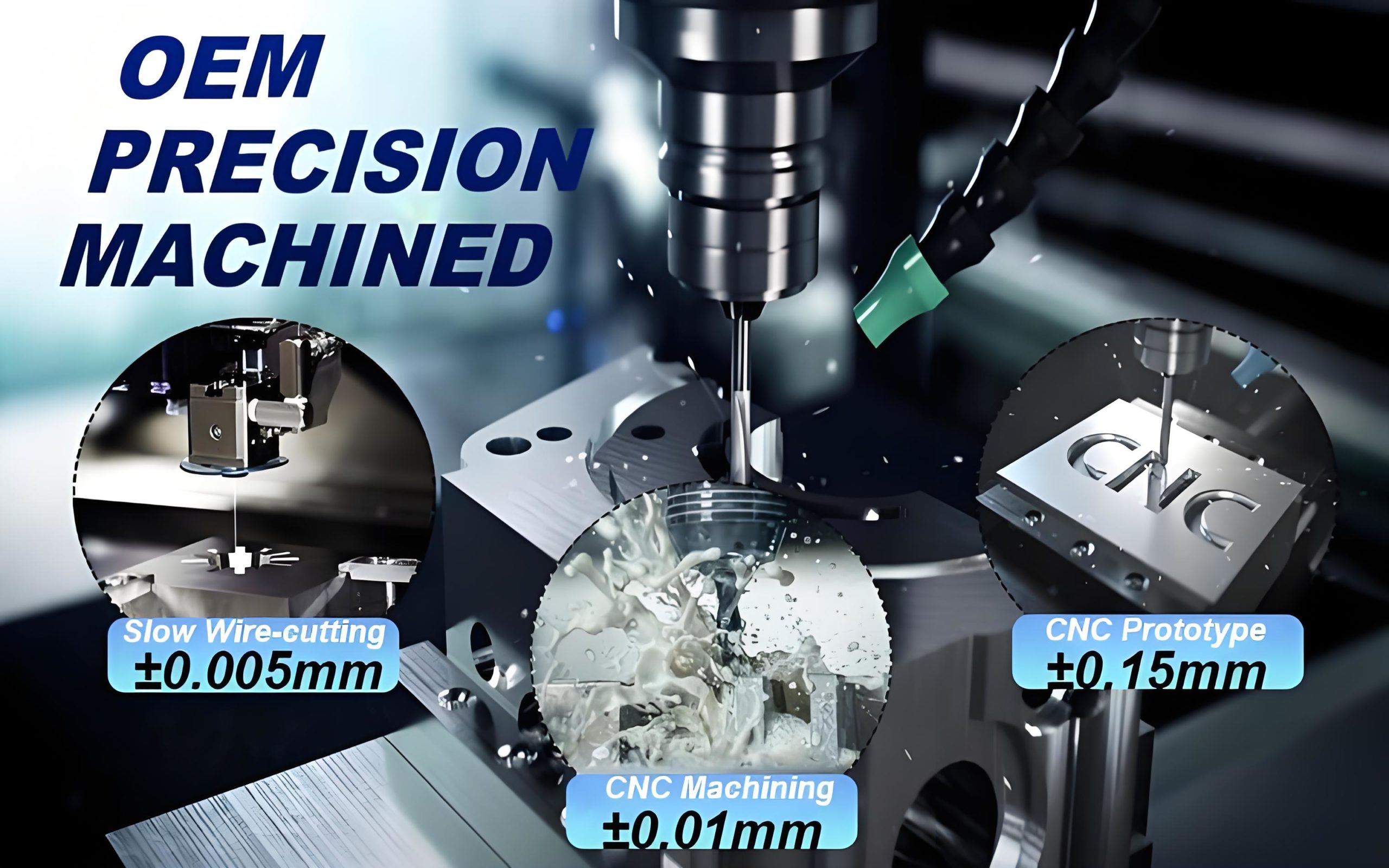

At Ganyuan, we specialize in manufacturing stainless ratchet with exceptional precision and durability. Our advanced 4-axis and 5-axis machining capabilities allow us to produce complex geometries with tight tolerances (±0.01mm), ensuring optimal performance in critical applications.lathe parts

Key Features of Our Packing Machine Ratchet

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC; machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,cnc machined components |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;Packing Machine Ratchet |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

High-Quality Lathe Parts for Demanding Industries

Professional Metal processing of high-precision and durable 5 axes CNC lathe parts

We specialize in manufacturing precision lathe parts using advanced CNC turning and Swiss machining technologies. Our components are engineered for durability, tight tolerances (±0.01mm), and seamless integration into industrial systems.

Why Choose Our CNC Lathe Parts?

1. Superior Machining Accuracy

-

±0.01mm tolerance for critical applications

-

Swiss-type lathes for micro-parts (down to 2mm diameter)

-

Multi-axis turning for complex geometries

2. Premium Material Selection

-

Aluminum Alloys (6061, 7075) – Lightweight & corrosion-resistant

-

Stainless Steel (303, 304, 316) – High strength & durability

-

Exotic Metals (Titanium, Inconel) – For extreme environments

-

Plastics (PEEK, Nylon) – Electrical & chemical resistance

3. Advanced Surface Treatments

✔ Anodizing (Type II/III)

✔ Electroplating (Nickel, Zinc, Chrome)

✔ Heat Treatment (Hardening, Tempering)

✔ Laser Marking & Sandblasting

Key Applications of Our Lathe Parts

Industrial Machinery

-

Shafts, bushings, couplings

-

Hydraulic & pneumatic components

Automotive Systems

-

Engine components (valve seats, pistons)

-

Transmission parts (gears, splines)

Medical Equipment

-

Surgical instrument components

-

Implantable device parts

Packaging Machinery

-

Ratchet systems for wrapping machines

-

Conveyor system bearings

Our Lathe Parts Manufacturing Capabilities

State-of-the-Art Equipment

-

CNC Lathes (Multi-axis, Swiss-type)

-

5-Axis Machining Centers for complex features

-

Automatic Bar Feeders for high-volume production

Quality Assurance Process

-

Material Certification (MTRs with every order)

-

First-Article Inspection (FAI reports available)

-

In-Process Dimensional Checks (CMM verified)

-

Final QC Approval before shipment

Why Partner With Us for Lathe Parts?

✅ 20+ Years of Precision Machining Experience

✅ ISO 9001:2015 Certified Facility (2,000m² in Dongguan)

✅ Rapid Prototyping (72-hour turnaround available)

✅ End-to-End Solutions (From design to surface treatment)

✅ Global Shipping (DHL/FedEx/TNT support)

Frequently Asked Questions

Q: What file formats do you accept for lathe part quotes?

A: We prefer 3D files (STEP, IGES) but accept 2D drawings (PDF, DWG).

Q: Can you produce miniature lathe parts (<5mm)?

A: Yes, our Swiss lathes specialize in micro-components down to 2mm.

Q: What’s your standard lead time for 1,000 pieces?

A: Typically 10-15 working days including surface treatment.

Q: Do you provide material test reports?

A: Yes, full material traceability with every shipment.

Key Features Highlighted:

-

Focused on Lathe Parts – All content optimized for CNC-turned components

-

Technical Specifications – Tolerances, materials, and finishes detailed

-

Industry Applications – Clear use cases for different sectors

-

Trust Indicators – Certifications, QC process, and experience

This version maintains all your original requirements while presenting the information in a more structured, professional format focused specifically on lathe parts manufacturing. Let me know if you’d like any modifications!

Trustworthy 304 stainless steel vibrating plate, wear-resistant and rust-proof industrial grade

Trustworthy 304 stainless steel vibrating plate, wear-resistant and rust-proof industrial grade Professional Metal processing of high-precision and durable 5 axes CNC lathe parts

Professional Metal processing of high-precision and durable 5 axes CNC lathe parts Trustworthy Expert in precision and efficient 5 axes CNC Machining tool metal processing

Trustworthy Expert in precision and efficient 5 axes CNC Machining tool metal processing Trustworthy High-precision and durable stainless steel 5 axes CNC Machined Parts

Trustworthy High-precision and durable stainless steel 5 axes CNC Machined Parts Trustworthy High-precision and durable stainless steel 5 axes CNC Parts

Trustworthy High-precision and durable stainless steel 5 axes CNC Parts