Stable quality OEM High Precision 5 axes CNC Turning Milling stainless steel production Parts Service Trusted

enquiry- Specifications

Dive into high - quality stainless steel production.Our experienced team creates stainless steel products with outstanding strength and aesthetic appeal.stainless steel production

Product Description

Stainless Steel Production: Precision Manufacturing for Demanding Applications

High-Performance Stainless Steel Components Engineered to Excellence

Our Stainless Steel Manufacturing Process stainless steel production

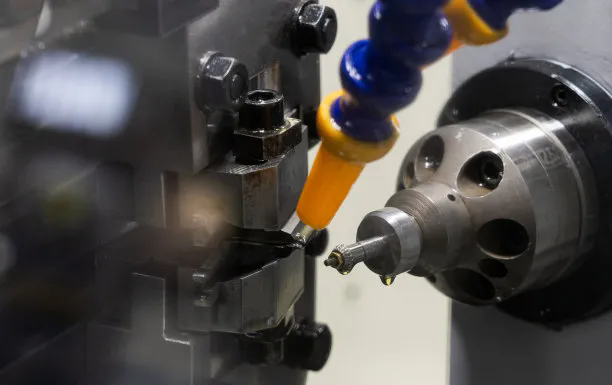

We combine advanced CNC technology with metallurgical expertise to deliver superior stainless steel products:

Stable quality OEM High Precision CNC Turning Milling stainless steel production Parts Service Trusted stainless steel production

✔ Precision 5-axis CNC machining for complex geometries

✔ Multi-stage surface treatments for enhanced durability

✔ Strict quality control ensuring ±0.01mm tolerances

✔ Material certification with full traceability

Key Material Advantages:

-

304/316 Stainless Steel: Optimal corrosion resistance

-

17-4PH: Precipitation-hardening for extra strength stainless steel production

-

Custom Alloys: Tailored to specific application needs

Featured Stainless Steel Products

1. Mask Machine Knurling Wheel

-

Material: 304 Stainless Steel

-

Process: CNC turning → 5-axis milling → Electroplating

-

Features: Precise grip pattern, wear-resistant surface

2. Industrial Equipment Brackets

-

Material: 316L Stainless Steel

-

Process: 5-axis CNC → Passivation

-

Benefits: Chemical resistance, structural integrity

3. Medical Device Components

-

Material: 17-4PH Stainless

-

Process: Precision milling → Electropolishing

-

Advantages: Biocompatible, sterilizable stainless steel production

Advanced Manufacturing Capabilities

State-of-the-Art Equipment:

-

5-axis CNC machining centers (DMG Mori, Mazak)

-

High-precision CNC lathes (Swiss-type available)

-

EDM/Wire cutting for complex contours

-

Automated finishing systems

Quality Assurance:

-

3D scanning for dimensional verification

-

Surface roughness measurement (Ra 0.4μm achievable)

-

Material composition analysis

-

Salt spray testing for corrosion resistance

Stainless Steel Applications by Industry

| Industry | Typical Components | Material Grade |

|---|---|---|

| Medical | Surgical tools, Implants | 316L, 17-4PH |

| Food Processing | Machinery parts, Valves | 304, 316 |

| Marine | Hardware, Fittings | 316, 2205 Duplex |

| Aerospace | Structural components | 15-5PH, Custom |

Surface Treatment Options

Functional Finishes:

-

Electropolishing (improves corrosion resistance)

-

Passivation (oxide layer enhancement)

-

TiN coating (wear reduction)

-

Bead blasting (uniform matte finish)

Aesthetic Treatments:

-

Mirror polishing (optical-grade)

-

PVD coating (gold, black, rainbow)

-

Brushed finishes (directional grain)

-

Custom etching/engraving

About Our Manufacturing Facility

Company Overview

🏭 20+ Years metal machining expertise

📍 2,000m² Facility in Dongguan, China

🛠️ Production Highlights:

-

ISO 9001:2015 certified processes

-

Medical-grade clean room available

-

Aerospace-compliant documentation

-

R&D team for custom alloys

Certifications:

-

ISO 13485 (Medical Devices)

-

AS9100 (Aerospace)

-

RoHS/REACH compliance

-

Material test reports (MTR)

Start Your Project Today:

Submit your design for:

-

Free manufacturability analysis

-

Material selection consultation

-

Competitive quotation

-

Prototype timeline

Our stainless steel specialists are ready to deliver components that meet your most demanding requirements for strength, corrosion resistance, and precision. Contact us to discuss your project needs.