Exquisite Aluminum CNC machine 5axes CNC Parts Custom Processing Copper Products Accessories

enquiry- Specifications

Durable Aluminum CNC machine – Precision-machined aluminum parts with excellent corrosion resistance and mechanical properties for long-lasting performance.

Our custom aluminum CNC parts offer unique design flexibility. They can be individually designed and manufactured according to the specific needs of customers. Whether it is complex structural shapes or fine internal features, they can all be realized through CNC machining.Aluminum CNC machine

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

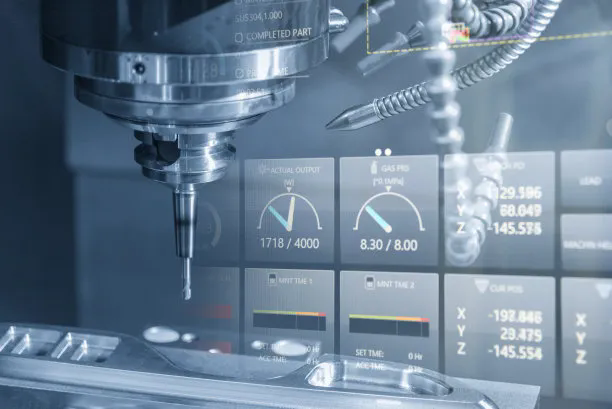

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,Aluminum CNC machine |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;Aluminum CNC machine |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Aluminum CNC Machine: Precision Machining for High-Performance Parts

Premium Aluminum Alloy Components for Demanding Applications

Why Choose Our Aluminum CNC Machining?

We deliver precision aluminum parts with exceptional properties:Aluminum CNC machine

Exquisite Aluminum CNC machine CNC Parts Custom Processing Copper Products Accessories Aluminum CNC machine

✔ Lightweight strength (60% lighter than steel)

✔ Superior corrosion resistance for long-term durability

✔ Tight tolerances (±0.02mm standard)

✔ Complex geometries via 5-axis machining

Material Advantages:

-

6061 Aluminum: Excellent all-purpose alloy

-

7075 Aluminum: Aerospace-grade strength

-

Natural oxidation resistance

-

Optimal thermal conductivity

Manufacturing Capabilities

Advanced CNC Machining Process:

-

High-speed milling (up to 20,000 RPM)

-

Precision turning for cylindrical features

-

Multi-axis contouring for complex shapes

-

Automated quality inspection (CMM available)Aluminum CNC machine

Surface Treatment Options:

-

Hard anodizing (up to 50μm)

-

Chemical film conversion

-

Powder coating

-

Electropolishing

Industry Applications

| Industry | Typical Components | Key Benefit |

|---|---|---|

| Aerospace | Structural frames | Weight reduction |

| Automotive | Engine parts | Heat dissipation |

| Robotics | Actuator housings | Precision movement |

| Electronics | Heat sinks | Thermal management |

Quality Assurance

Comprehensive Testing Protocol:

-

Material certification verification

-

First-article 3D scanning

-

In-process dimensional checks

-

Surface roughness analysis

-

Functional performance testing

Certifications:

-

ISO 9001:2015 compliant

-

AS9100 aerospace standards

-

RoHS compliance

-

Full material traceability

Technical Specifications

| Parameter | Capability |

|---|---|

| Maximum Part Size | 800×600×500mm |

| Tolerance Standard | ±0.02mm (±0.01mm available) |

| Surface Finish | Ra 0.8-3.2μm |

| Minimum Feature Size | 0.5mm |

| Production Lead Time | 15 days standard |

Why Partner With Us?

✅ 20+ years aluminum machining expertise

✅ Prototype to production services

✅ Engineering support from design to delivery

✅ Competitive pricing with low MOQs

✅ Fast turnaround without quality compromise

Start Your Project Today:

Submit your CAD files for:

-

Free manufacturability analysis

-

Material selection guidance

-

Competitive quotation

-

Production timeline

Our CNC machining specialists combine advanced technology with material expertise to deliver high-quality aluminum components that meet your exact specifications. Contact us to discuss your requirements.