Trustworthy Supply Machining, Aluminum Cutting, Copper Products and Stainless 5 axes Steel Parts Production

enquiry- Specifications

Need reliable aluminum cutting solutions? We offer customized services, tailoring cuts to your specific requirements for a wide range of aluminum applications.Aluminum Cutting

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,Aluminum Cutting |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts; Aluminum Cutting |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

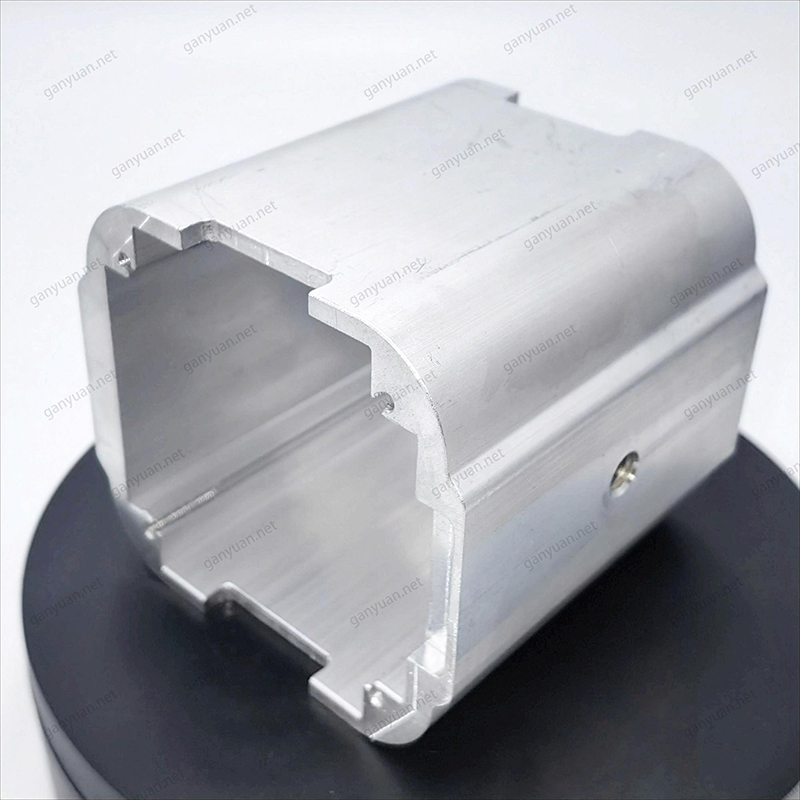

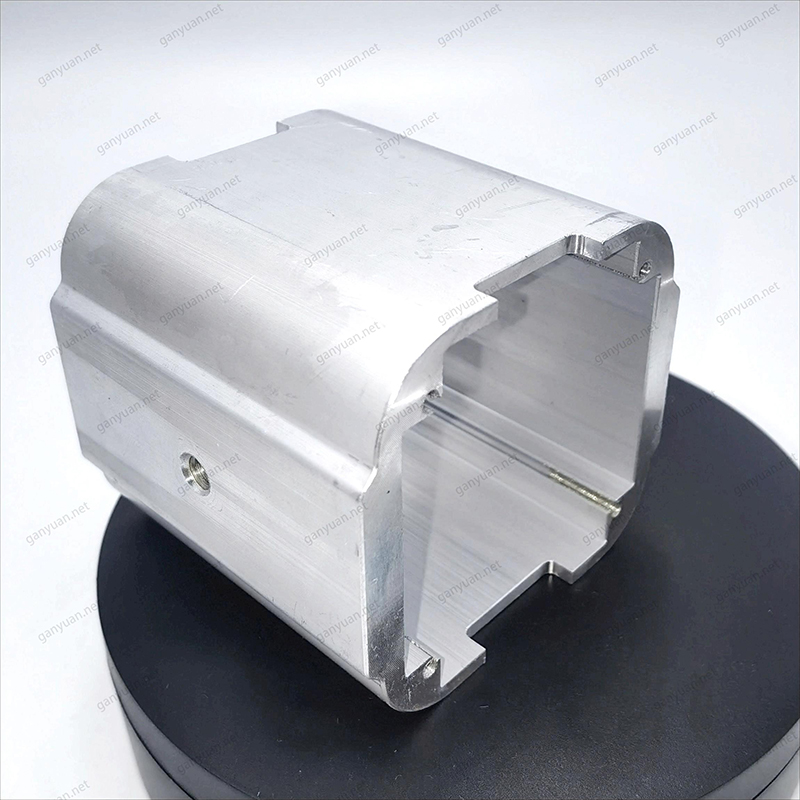

Custom CNC Machined Aluminum Solutions Aluminum Cutting

At Ganyuan Precision Manufacturing, we specialize in high-precision aluminum cutting services that deliver exceptional results for demanding industrial applications. Our capabilities include:

-

CNC milling & turning of aluminum components

-

5-axis machining for complex geometries

-

Tolerances to ±0.01mm for precision parts

-

Trustworthy Supply Machining, Aluminum Cutting, Copper Products and Stainless 5 axes Steel Parts Production

Surface finishes from Ra 0.8 to 3.2

Why Choose Our Aluminum Cutting Services?

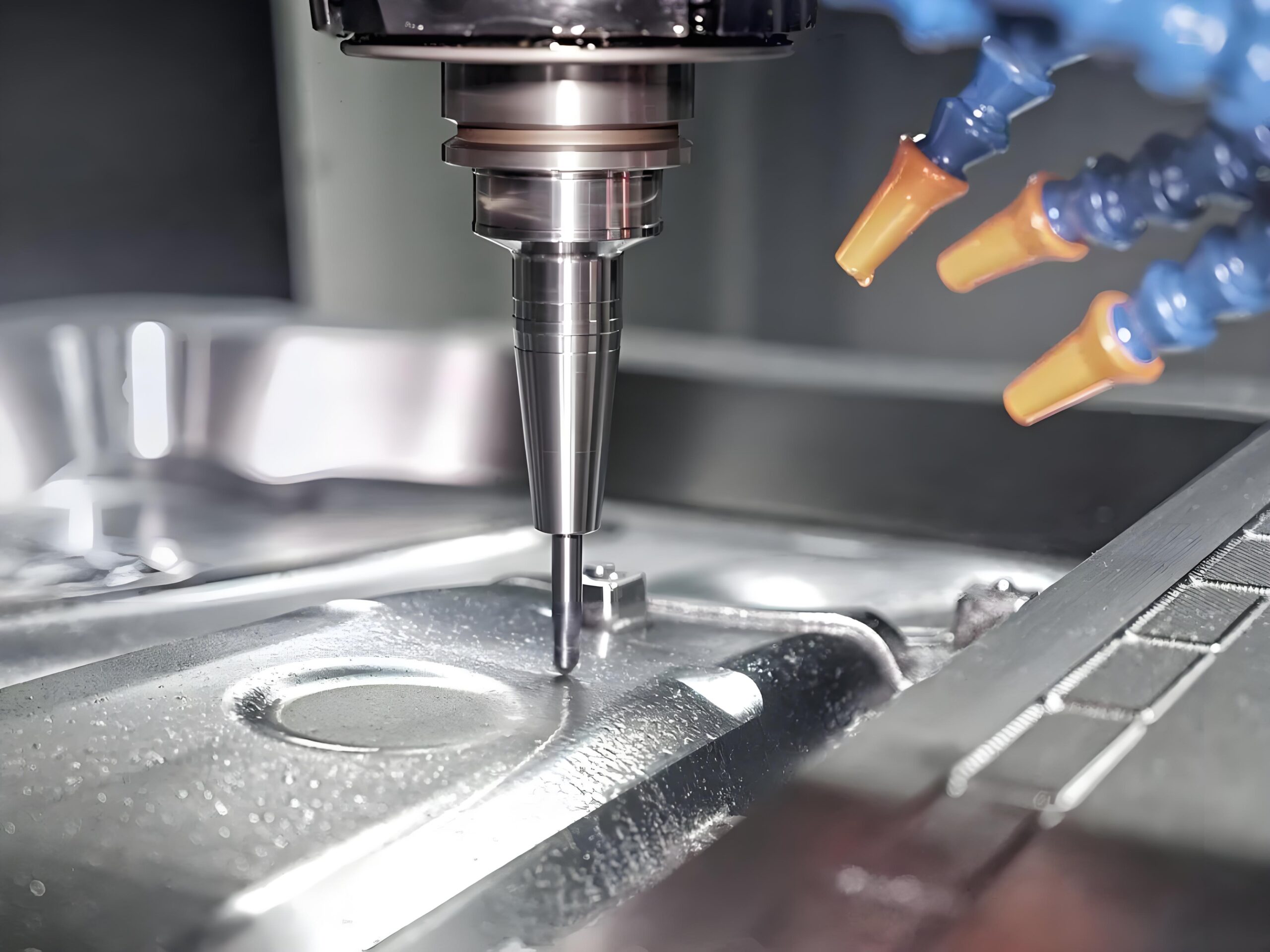

1. Advanced Machining Technology

Our German-engineered CNC centers provide:

-

High-speed machining up to 20,000 RPM

-

Rigid tapping and thread milling capabilities

-

4th/5th axis simultaneous machining

-

Automated tool changing systems

2. Premium Aluminum Materials

We work with all standard and specialty alloys:

-

6061-T6 - Excellent all-purpose alloy

-

7075-T6 - Aerospace-grade strength

-

2024 - High fatigue resistance

-

5052 - Superior corrosion resistance

3. Complete Manufacturing Solutions

-

Prototype to high-volume production

-

Secondary operations (drilling, tapping, etc.)

-

Comprehensive surface finishing options

-

Strict quality control protocols

Aluminum Cutting Capabilities

| Specification | Detail |

|---|---|

| Max Part Size | 600 × 400 × 300mm |

| Tolerance | ±0.01mm standard |

| Surface Finish | Ra 0.8 achievable |

| Material Thickness | 0.5mm to 150mm |

| Lead Time | 5-10 working days |

Industries We Serve

With 20+ years of machining expertise, we deliver precision aluminum components for:

✔ Aerospace & defense

✔ Automotive systems

✔ Electronics enclosures

✔ Industrial machinery

✔ Robotics & automation

Get Your Custom Aluminum Parts Quote

Fast response · Competitive pricing · Reliable delivery

Our engineering team is ready to help with your aluminum cutting needs.

[Contact Us Today] for:

-

Immediate quoting

-

Design for manufacturability advice

-

Material selection guidance

Ganyuan Precision Manufacturing - Your Trusted Partner for Precision Aluminum Machining

Key Advantages:

• 2,000 sqm advanced manufacturing facility

• ISO 9001 certified quality system

• 5-axis simultaneous machining

• Comprehensive metrology lab

• Just-in-time delivery available

Packing&Shipping