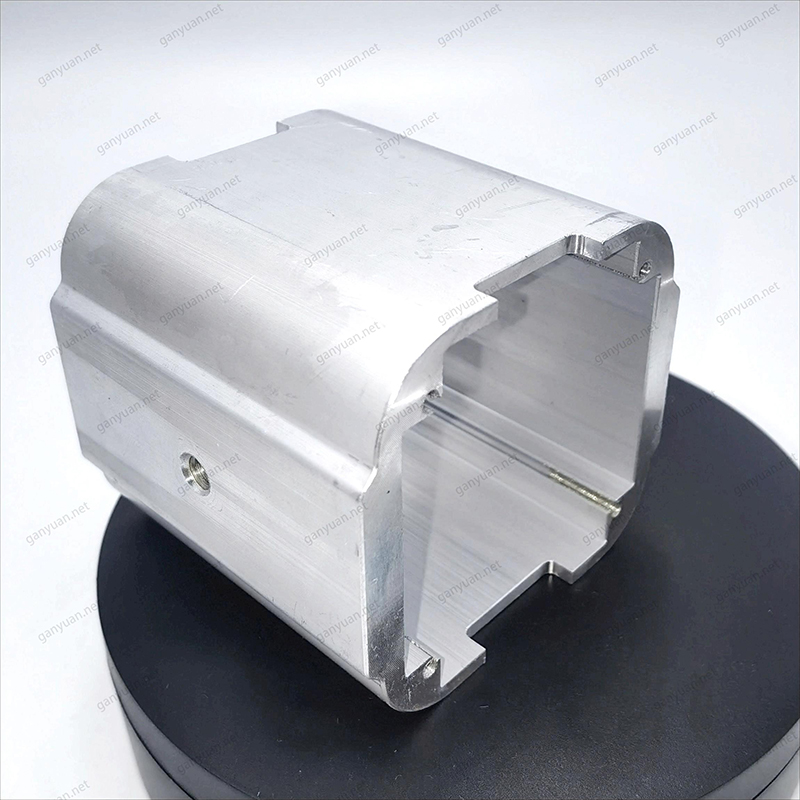

High-end customized aluminium alloy 6061 material is sturdy and resistant to oxidation

enquiry- Specifications

Ganyuan is a manufacturer with more than ten years of CNC machine tool processing, manufacturing and customization, specializing in the processing of various precision machinery parts. The company has various types of imported and domestic CNC lathes, lathes, precision milling machines, three-dimensional measuring instruments and other testing equipment. Not only can we produce a variety of complex non-standard automation parts and hardware parts, we can also customize various hardware processing parts according to the user's professional wholesale requirements with drawings and samples.aluminium alloy 6061

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

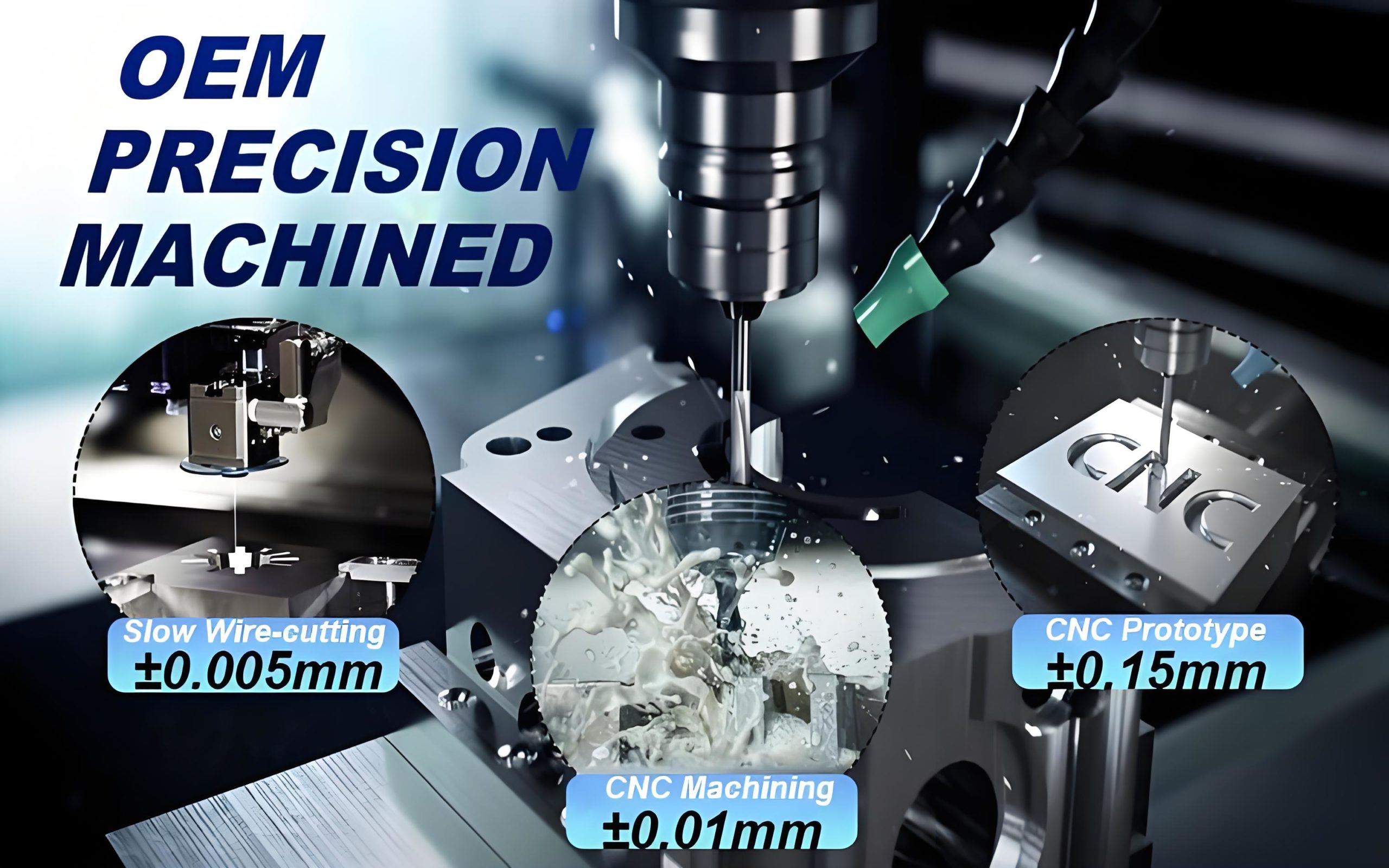

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,cnc machined components |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;aluminium alloy 6061 |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Aluminium Alloy 6061: Superior Material Properties for High-Stress Applications

High-end customized aluminium alloy 6061 material is sturdy and resistant to oxidation

Enhance your engineering projects with aluminium alloy 6061, a versatile and reliable material renowned for its exceptional strength-to-weight ratio and corrosion resistance. Ideal for aerospace, automotive, electronics, and high-performance sports equipment, this alloy delivers outstanding performance in demanding environments.

Aluminium Alloy 6061: Excellent Lightweight Properties

One of the standout features of aluminium alloy 6061 is its extremely low density, which significantly reduces weight compared to traditional metals. This makes it a preferred choice in industries where weight reduction is critical:

-

Aerospace: Reduces aircraft weight, improving fuel efficiency, payload capacity, and flight performance.

-

Automotive: Enhances fuel economy and vehicle dynamics while maintaining structural integrity.

-

High-End Sports Equipment: Provides superior portability and controllability in bicycles, drones, and other performance gear.

Aluminium Alloy 6061: Superior Machinability for Precision Parts

Aluminium alloy 6061 is exceptionally well-suited for CNC turning and milling, allowing for complex geometries and tight tolerance control. Its excellent machinability ensures:

-

High-precision parts that meet strict industry standards.

-

Smooth surface finishes with minimal tool wear.

-

Compatibility with intricate designs for aerospace, medical, and electronic applications.

Our advanced 5-axis CNC, 4-axis CNC, and multi-tasking lathes guarantee precision and efficiency in every component we produce.

Aluminium Alloy 6061: Our Manufacturing Expertise

We are a leading CNC machining manufacturer based in Dongguan, China, with over 20 years of experience in precision engineering. Our facility spans 2,000 square meters and is equipped with:

-

High-end CNC machines (5-axis, 4-axis, Swiss-type lathes)

-

Stamping & die-casting equipment

-

Advanced surface treatments (anodizing, electroplating, powder coating, etc.)

-

Strict quality control (3D scanning, hardness testing, CMM inspection)

Aluminium Alloy 6061: Custom Solutions for Every Industry

We specialize in machining aluminium alloy 6061 parts for:

✔ Aerospace (brackets, housings, structural components)

✔ Automotive (engine parts, suspension components)

✔ Electronics (heat sinks, enclosures, connectors)

✔ Medical Devices (surgical instruments, implants)

✔ Robotics & Industrial Machinery (gears, actuators, frames)

Aluminium Alloy 6061: Surface Treatment Options

To enhance durability and aesthetics, we offer a wide range of surface treatments:

-

Anodizing (improves corrosion & wear resistance)

-

Powder Coating & Painting (custom colors & textures)

-

Electroplating (gold, silver, nickel, chrome finishes)

-

Sandblasting & Polishing (smooth, refined surfaces)

-

Laser Marking & Engraving (permanent branding)

Why Choose Our Aluminium Alloy 6061 Machining Services?

✅ High-Quality Materials – Sourced from trusted suppliers with full material certifications.

✅ Precision Manufacturing – Tight tolerances (±0.005mm) for critical applications.

✅ Fast Turnaround – Prototyping & mass production with quick lead times.

✅ Competitive Pricing – Cost-effective solutions without compromising quality.

✅ End-to-End Support – From design to delivery, we ensure seamless production.

Packing&Shipping