Trustworthy High-strength aluminum spacers 6061 CNC machined parts, aviation-grade material

enquiry- Specifications

If you have any custom aluminum spacers parts or custom aluminum alloy milling machine parts, please send us the drawings immediately to start the quotation process. We fully support the receipt of documents in PDF/DWG/STP/IGS and other formats, aiming to provide you with a convenient and efficient customized service experience.aluminum spacers

Product Description aluminum spacers

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,aluminum spacers |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;custom carbon fiber parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Aluminum Spacers: Precision Machined for Perfect Fitment

Custom Aluminum Spacer Solutions for Every Application

Why Choose Our Aluminum Spacers?

We manufacture precision spacers with exceptional quality:

Trustworthy High-strength aluminum spacers 6061 CNC machined parts, aviation-grade material

✔ Tight tolerances (±0.015mm achievable)

✔ Material versatility (6061/7075/2024 aluminum)

✔ Custom configurations for unique requirements

✔ Multiple surface treatment options

Key Benefits:

-

Lightweight yet durable construction

-

Excellent corrosion resistance

-

Precise dimensional stability

-

Cost-effective production solutions

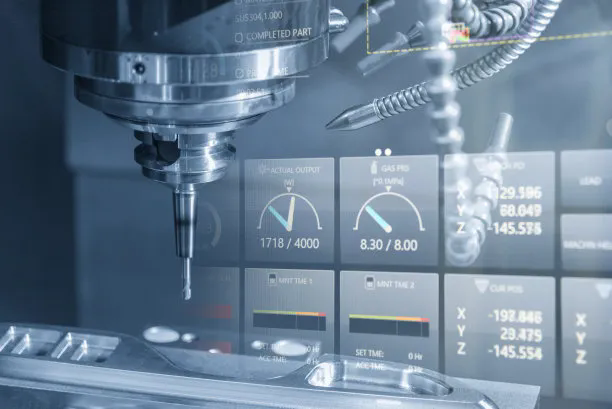

Manufacturing Excellence

Advanced Production Process:

-

CNC turning/milling for precise dimensions

-

5-axis machining for complex geometries

-

Surface finishing to specifications

-

Quality inspection at every stage

Material Options:

-

6061-T6 Aluminum (general purpose)

-

7075-T6 Aluminum (high strength)

-

2024 Aluminum (aerospace applications)

-

Custom alloys available

Industry Applications

| Industry | Typical Uses | Key Advantage |

|---|---|---|

| Aerospace | Structural spacing | Lightweight strength |

| Automotive | Engine components | Heat dissipation |

| Electronics | Circuit board mounts | Electrical insulation |

| Industrial | Machinery alignment | Vibration damping |

Quality Assurance

Comprehensive Testing:

-

Dimensional verification (CMM)

-

Surface hardness testing

-

Material certification

-

Functional fit testing

-

Anodizing thickness measurement

Surface Treatment Options

Functional Finishes:

-

Hard anodizing (Type II/III)

-

Chemical conversion coating

-

Electroless nickel plating

-

Powder coating

Aesthetic Finishes:

-

Color anodizing (multiple options)

-

Mirror polishing

-

Bead blasting

-

Laser marking

Technical Specifications

| Parameter | Capability |

|---|---|

| Diameter Range | 2-200mm |

| Length Range | 1-500mm |

| Tolerance | ±0.015mm |

| Surface Finish | Ra 0.8-3.2μm |

| Lead Time | 10-15 days |

Why Partner With Us?

✅ 20+ years precision machining experience

✅ Design for Manufacturing (DFM) support

✅ Low MOQ flexibility (prototype to production)

✅ Competitive pricing without quality compromise

✅ Fast turnaround with reliable delivery

Start Your Spacer Project:

Submit your drawings (PDF/DWG/STEP/IGES) for:

-

Free design evaluation

-

Material recommendations

-

Competitive quotation

-

Production timeline

Our engineering team specializes in precision aluminum spacers for critical applications. Contact us today to discuss your specific requirements.