Trustworthy 5-axis CNC lathe to produce brass precision parts copper processing China

enquiry- Specifications

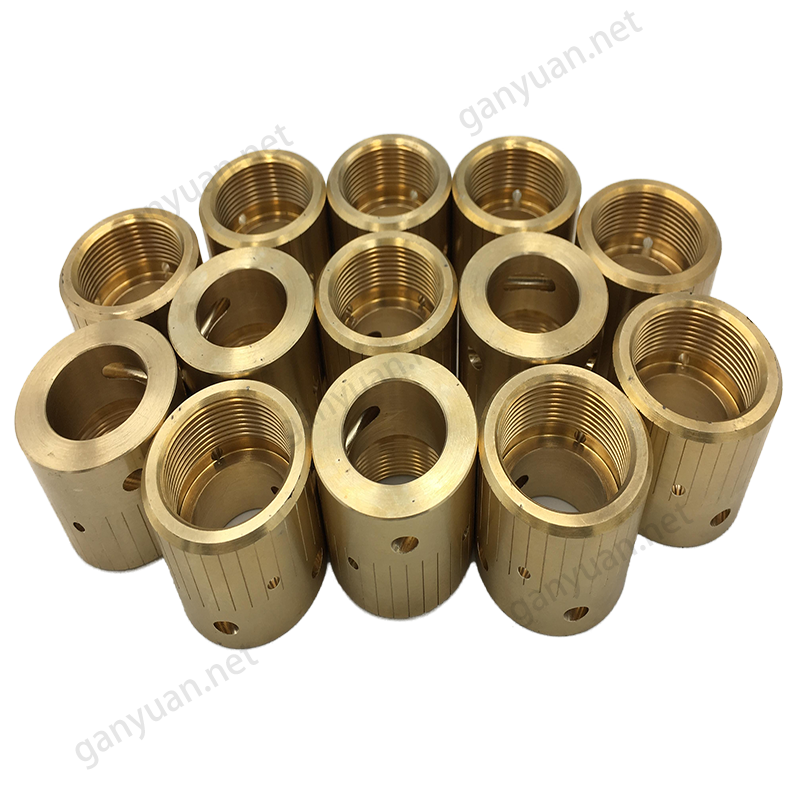

At Ganyuan, we specialize in manufacturing premium brass precision parts with tolerances as tight as ±0.02mm. Our advanced CNC machining capabilities transform high-grade brass alloys into reliable components for demanding industrial applications.brass precision parts

Why Choose Our Brass Precision Parts?

| Production type | Custom production and processing | Material | Metal,plastic machining, carbon steel, stainless steel, copper, aluminum alloy,brass precision parts |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, brass precision parts |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;brass precision parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

1. Advanced Machining Technology

-

5-axis CNC milling for complex geometries

-

Swiss-type turning for micro components

-

CAD/CAM optimized tool paths brass precision parts

-

Automated quality inspection systems

High-precision brass parts for industries requiring corrosion resistance and excellent machinability. Custom solutions with tight tolerances.brass precision parts

2. Superior Material Properties

-

Excellent corrosion resistance

-

High electrical/thermal conductivity

-

Superior machinability (C36000)

-

Antimicrobial properties (C46400)

3. Rigorous Quality Control

-

Raw material certification

-

First-article inspection

-

In-process dimensional checks

-

Final CMM verification

-

Surface roughness testing brass precision parts

Manufacturing Capabilities

-

Complex Shapes: Threads, grooves, undercuts

-

Thin-Wall Machining: Down to 0.3mm

-

Micro Components: Minimum Ø0.5mm

-

High-Volume Production: 50,000+ monthly capacity brass precision parts

Surface Treatment Options

-

Electroplating: Nickel, Chrome, Gold, Silver

-

Chemical Film: Chromate conversion coating

-

Polishing: Mirror, satin, brushed finishes

-

Laser Marking: Permanent identification

Packing&Shipping

FAQ

Contact Our Brass Machining Experts Today

📧 Email: ganyuan1688@gmail.com

🌐 Website: ganyuan1688@gmail.com

📞 Tel: 86–13929256361

Why Partner With Us?

→ Precision Brass Components (±0.02mm tolerance)

→ Advanced 5-Axis Machining

→ Fast Turnaround (10-15 day lead time)

→ Industry-Specific Solutions

→ Competitive Pricing

Elevate Your Projects with Precision-Machined Brass Components!