cam parts Stable quality non-standard production and processing 4-axis China

enquiry- Specifications

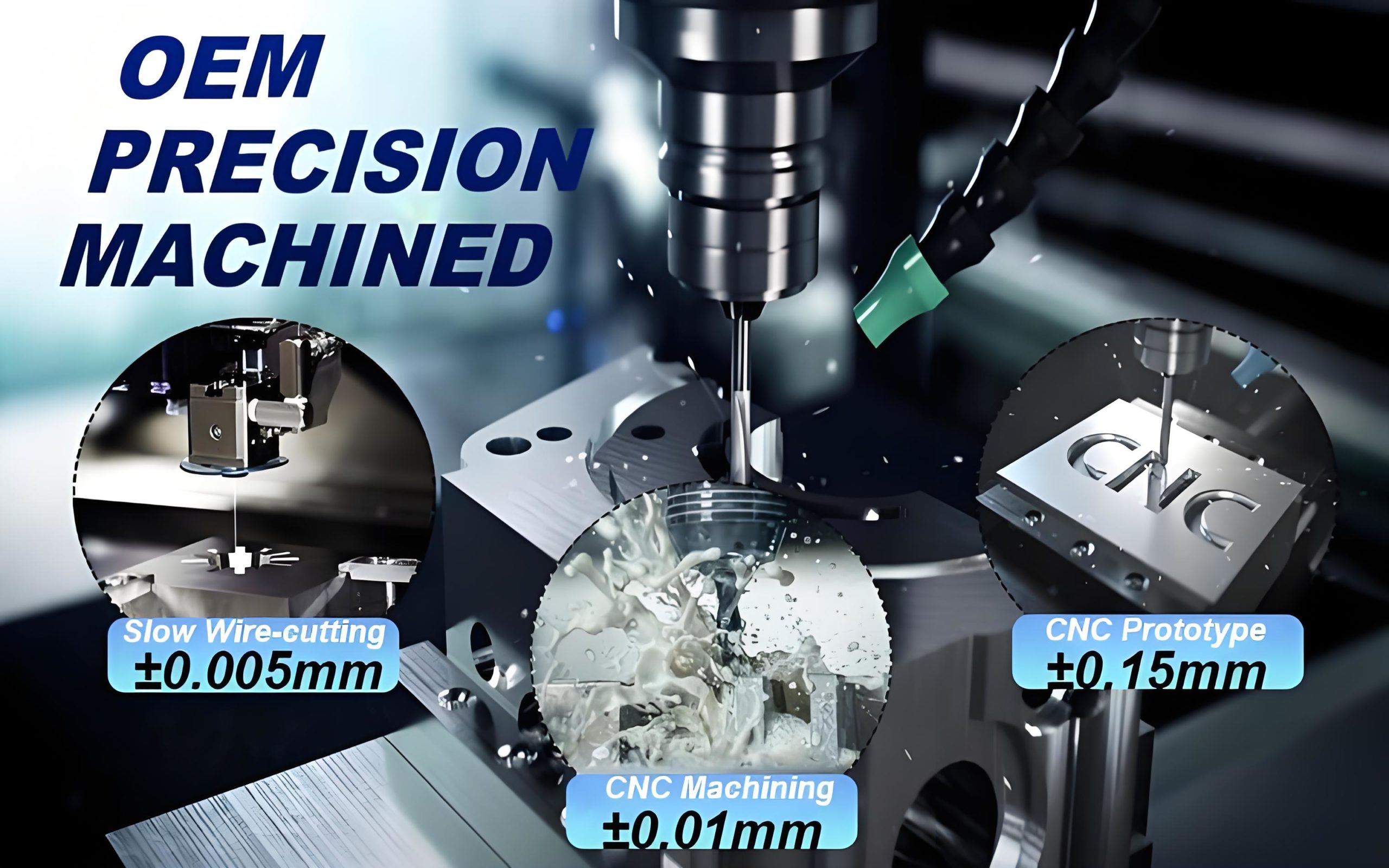

Our cam parts undergo precision machining through advanced CNC lathe and 4-axis CNC milling processes, ensuring exceptional dimensional accuracy and surface quality for demanding mechanical applications.cam parts

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,cam parts |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;cam parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

cam parts Manufacturing Process

1. CNC Lathe Processing (Primary Machining)

-

Performs roughing and finishing of outer diameters and end faces

-

Achieves IT6-IT7 dimensional accuracy

-

Ensures surface roughness Ra 0.8μm or better

2. 4-Axis CNC Milling (Complex Contouring)

-

Machines precise cam profiles through 4-axis simultaneous interpolation

-

Processes grooves/special contours with ≤0.02mm profile tolerance

-

Uses high-speed machining for optimal surface finish

3. Quality Assurance

-

In-process inspection with coordinate measuring machines (CMM)

-

100% surface roughness verification

-

Final hardness testing per application requirements

Why Choose Our cam parts Manufacturing?

With 20+ years of precision machining experience, our Dongguan facility offers:

-

2,000m² production area with dedicated knurling equipment

-

In-house heat treatment for controlled hardness

-

100% quality inspection including runout testing

-

DFM support to optimize your wheel design

Our factory has a plant area of about 2,000 square meters and masters core processing technologies. It has high-end precision production equipment: CNC lathes, 5-axis CNC, 4-axis CNC, stamping equipment, die-casting equipment, etc.cam parts

If you are interested in our products, please contact me and I will provide the best price support and quality service.

4-axis CNC milling

I believe we will establish a good and long-term cooperation.

Welcome to send pictures and letters to discuss, thank you!

Our Adrantages

We cooperate with many high-quality material suppliers, and the quality is very guaranteed. Please feel free to choose our materials. At the same time, supporting documents can be provided for all materials. Materials are available, such as aluminum alloy, steel alloy, carbon steel, stainless steel, copper, brass, titanium alloy, bronze, nylon, acrylic, cnc machined components,etc.cam parts

Aluminum 6061/6063/7075; Iron 1215/45/1045; Stainless steel 303/304/316; Copper; Brass; Bronze (H59/H62/T2/H65); Plastic POM/PE/PSU/PA/PEEK, etc. can be based on Customer requirements.

4-axis CNC milling Technical Advantages

✔ Dual-Process Integration - Combines turning and 4-axis CNC milling for complete cam fabrication

✔ Complex Geometry - 4-axis capability handles non-standard cam parts profiles

✔ Material Versatility - Processes carbon steel (1045/4140), stainless (303/304), and alloy steels

✔ Surface Enhancement - Optional nickel plating (15-50μm) or hard chrome (up to HRC62)

Surface Treatment Options

• Precision polishing (mirror/matte)

• Electroless nickel plating

• Hard anodizing (for aluminum cams)

• PVD coating for special applications

Aluminum alloy surface oxidation

Dust-free electroless nickel plating on carbon steel surface

Packaging & Service

-

Secure Packaging: Anti-rust oil + Bubble wrap + Wooden cases

-

OEM/ODM Services: Provide samples or drawings (PDF/STEP/IGS formats accepted)

-

Global Shipping: DHL/FedEx/Sea freight supported

FAQ

Upgrade Your Mask Machine Today!

Contact us for:

✓ Custom pattern design consultations

✓ Material selection advice

✓ Competitive volume pricing

[Contact Now] for your free engineering evaluation