Processing of high-strength carbon steel shaft parts with stable quality 5axes

enquiry- Specifications

Our carbon steel shafts stand out. Engineered with advanced techniques, they provide optimal torque transmission and durability, ideal for heavy - duty operations.

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,carbon steel shaft |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts; carbon steel shaft |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Carbon Steel Shafts: High-Strength Solutions for Heavy-Duty Applications

Precision Machined Carbon Steel Shafts for Demanding Operations

Why Choose Our Carbon Steel Shafts?

We manufacture durable shafts that deliver:

Processing of high-strength carbon steel shaft parts with stable quality

✔ Exceptional strength for high-torque applications

✔ Precision machining (±0.02mm tolerances)

✔ Custom configurations to your specifications

✔ Multiple surface treatment options

Key Advantages:

-

Superior load-bearing capacity

-

Excellent wear resistance

-

Cost-effective solution

-

Reliable performance under stress

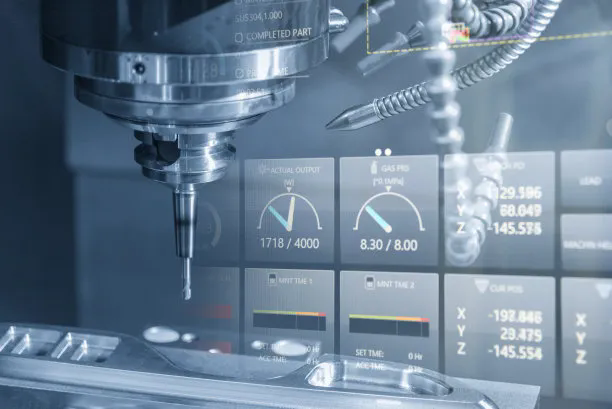

Manufacturing Excellence

Advanced Production Process:

-

CNC turning for precise diameters

-

Precision grinding for critical surfaces

-

Heat treatment for enhanced durability

-

Surface finishing for performance

-

Quality validation at every stage

Material Options:

-

1045 Carbon Steel: General purpose

-

4140 Alloy Steel: High strength

-

4340 Alloy Steel: Toughness

-

Custom alloys available

Industry Applications

| Industry | Typical Uses | Key Benefit |

|---|---|---|

| Automotive | Axles, Driveshafts | High torque capacity |

| Industrial | Gear shafts, Rotors | Wear resistance |

| Construction | PTO shafts, Hydraulics | Structural integrity |

| Agriculture | Implement shafts | Impact resistance |

Quality Assurance

Comprehensive Testing Protocol:

-

Material certification

-

Hardness testing

-

Dimensional verification (CMM)

-

Surface finish analysis

-

Functional performance testing

Surface Treatment Options

Functional Finishes:

-

Induction hardening

-

Nitriding for wear resistance

-

Chrome plating

-

Black oxide coating

Protective Coatings:

-

Powder coating

-

Zinc plating

-

Phosphate coating

-

Electroless nickel

Technical Specifications

| Parameter | Capability |

|---|---|

| Diameter Range | 5-300mm |

| Length Capacity | Up to 2000mm |

| Tolerance | ±0.02mm (±0.01mm available) |

| Surface Finish | Ra 0.8-3.2μm |

| Hardness | HRC 20-60 |

Why Partner With Us?

✅ 20+ years shaft manufacturing experience

✅ Prototype to production services

✅ Engineering support for optimal design

✅ Competitive pricing with low MOQs

✅ Fast turnaround (15-day standard)

Start Your Project:

Submit your requirements for:

-

Free design consultation

-

Material recommendations

-

Competitive quotation

-

Production timeline

Our specialists create high-performance carbon steel shafts for the most demanding applications. Contact us today to discuss your requirements.

Packing&Shipping