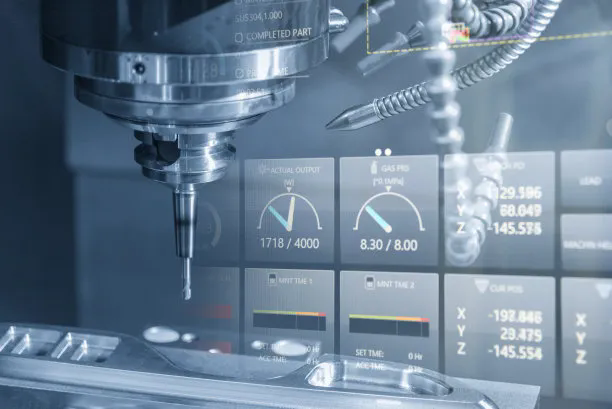

Outstanding 5-axis CNC lathes for processing metal and hardware parts of wheels

enquiry- Specifications

Discover high-precision CNC machine for wheels manufacturing CNC lathes, designed to deliver flawless finishes and unmatched durability for automotive and industrial applications.CNC lathes

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,CNC lathes |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;cnc machine for wheels |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

CNC Lathes: Precision Turning Solutions for Wheel Manufacturing

High-Performance CNC Turning for Automotive and Industrial Wheels

Why Choose Our CNC Lathe Services?

We deliver precision wheel components with:CNC lathes

Outstanding five-axis CNC lathes for processing metal and hardware parts of wheels CNC lathes

✔ Ultra-tight tolerances (±0.02mm standard)

✔ Large-capacity turning (up to Ø500mm)

✔ Advanced automation for high-volume production

✔ Superior surface finishes (Ra 0.8μm achievable)

Key Applications:

-

Automotive alloy wheels

-

Industrial pulley wheels

-

Gear wheels and sprockets

-

Custom wheel hubs

Manufacturing Capabilities

State-of-the-Art Equipment:

-

Heavy-duty CNC lathes for large diameter work

-

Multi-axis turning centers with live tooling

-

Automated loading systems for production runs

-

In-process measurement for quality control

Material Expertise:

-

Aluminum Alloys: 6061, 7075 (lightweight wheels)

-

Stainless Steel: 303, 304 (corrosion resistant)

-

Carbon Steel: 1045, 4140 (high strength)

-

Exotic Alloys: Titanium, Inconel (specialty applications)

Quality Assurance Process

Comprehensive Inspection Protocol:

-

Material certification verification

-

First-article 3D scanning

-

Runout and balance testing

-

Surface finish analysis

-

Functional performance validation

Certifications:

-

IATF 16949 automotive standards

-

ISO 9001:2015 compliant

-

Full material traceability

-

PPAP documentation available

Surface Treatment Options

Functional Finishes:

-

Hard anodizing (for aluminum wheels)

-

Chrome plating (decorative/protective)

-

Powder coating (durable colors)

-

Electroless nickel (wear resistance)

Specialty Treatments:

-

Diamond-cut machining

-

Custom laser etching

-

Two-tone finishes

-

Clear coat protection

Why Partner With Ganyuan?

✅ 20+ years wheel manufacturing experience

✅ Complete prototyping to production

✅ Engineering support for optimal designs

✅ Competitive pricing with low MOQs

✅ Fast turnaround (15-day standard)

Start Your Wheel Project:

Submit your CAD files for:

-

Free manufacturability review

-

Material recommendations

-

Competitive quotation

-

Production timeline

Our CNC lathe specialists combine advanced turning technology with wheel manufacturing expertise to deliver precision components that meet your exact specifications. Contact us today to discuss your requirements.

Packing&Shipping