Reliable Precision Machinery 5 axes cnc machining parts Grinder Auto Parts

enquiry- Specifications

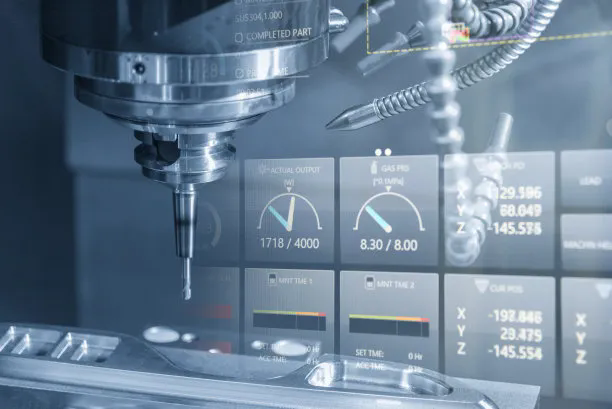

CNC machining parts: Precise, reliable, and crafted with advanced technology,expertly manufactured for optimal performance.

Dongguan Ganyuan Hardware Technology Co., Ltd., specializes in manufacturing and supplying customized machine parts. With our precision machining services, we provide a wide range of industrial machine parts, including aluminum and steel components. Our expertise extends to automotive, aerospace, and electronic components, as well as plastic injection molding services. We offer contract manufacturing services and integrated solutions for all your industrial equipment part needs.CNC machining parts

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,CNC machining parts |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;cnc machining parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

CNC Machining Parts: Precision Components for Automotive Excellence

High-Quality CNC Machined Automotive Components CNC machining parts

Why Choose Our CNC Machining Services?

We deliver precision automotive parts with industry-leading capabilities:cnc machining parts

Reliable Precision Machinery 5 axes cnc machining parts Grinder Auto Parts cnc machining parts

✔ Tight tolerances (±0.02mm standard)

✔ Multi-material expertise from aluminum to titanium

✔ Advanced 5-axis machining for complex geometries

✔ Fast 15-day turnaround for production orders

Key Automotive Applications:

-

Engine components (crankshafts, cylinder blocks)

-

Transmission systems (gears, shafts)

-

Suspension components (control arms, brackets)

-

Body structural parts and custom wheels

Manufacturing Excellence

State-of-the-Art Equipment:

-

5-axis CNC machining centers for complex contours

-

High-precision CNC lathes with live tooling

-

Swiss-type machining for small diameter parts

-

Automated inspection systems (CMM, optical comparators)

Material Options:

-

Aluminum Alloys: 6061-T6, 7075-T6

-

Stainless Steel: 303, 304, 316

-

Carbon Steel: 1045, 4140

-

Exotic Metals: Titanium, Inconel

Quality Assurance Process

Comprehensive Inspection Protocol:

-

Raw material certification

-

First-article 3D scanning

-

In-process dimensional verification

-

Surface finish analysis

-

Functional performance testing

Certifications:

-

IATF 16949 compliant

-

PPAP documentation available

-

Full material traceability

-

RoHS/REACH compliance

Surface Treatment Options

Functional Finishes:

-

Hard anodizing (for aluminum components)

-

Electroless nickel plating

-

Nitriding for wear resistance

-

Passivation for corrosion protection

Aesthetic Finishes:

-

Mirror polishing (Ra 0.4μm)

-

Bead blasting (uniform matte)

-

Custom powder coating

-

Laser engraving for markings

Why Partner With Us?

✅ 20+ years automotive machining experience

✅ Prototype to production services

✅ Engineering support from design to delivery

✅ Competitive pricing with low MOQ (10pcs)

✅ Strict confidentiality protocols

Start Your Project Today:

Submit your CAD files for:

-

Free manufacturability analysis

-

Material selection consultation

-

Competitive quotation

-

Production timeline

Our CNC machining specialists combine advanced technology with automotive manufacturing expertise to deliver precision components that exceed industry standards. Contact us to discuss your project requirements.