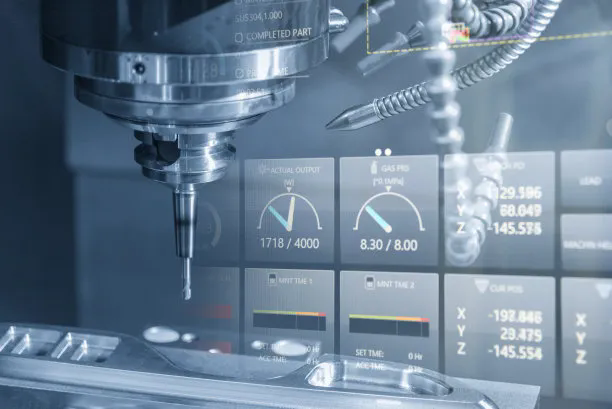

Trustworthy Professional 5-axis CNC milling machine production and processing

enquiry- Specifications

Find reliable CNC milling machine for precision machining, delivering consistent results and high efficiency for small to large-scale manufacturing needs.CNC milling machine

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,cnc milling machine |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;cnc milling machines |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

CNC Milling Machines: Precision Aluminum Alloy Machining Solutions

High-Performance CNC Milling Services for Industrial Applications

Why Choose Our CNC Milling Services?

We deliver precision aluminum alloy components with:CNC milling machine

Professional 5-axis CNC milling machine production and processing CNC milling machine

✔ Lightweight construction (60% lighter than steel)

✔ Tight tolerances (±0.02mm standard)

✔ Complex geometries via 5-axis machining

✔ Superior surface finishes (Ra 0.8μm achievable)

Key Material Advantages:

-

Excellent strength-to-weight ratio

-

Superior thermal conductivity

-

Natural corrosion resistance

-

Optimal machinability for complex designs

Advanced Manufacturing Capabilities

State-of-the-Art Equipment:

-

5-axis CNC milling centers for complex contours

-

High-speed machining (up to 20,000 RPM)

-

Precision CNC turning for cylindrical components

-

Automated quality inspection systems

Aluminum Alloy Options:

-

6061-T6: General purpose applications

-

7075-T6: Aerospace-grade strength

-

2024-T3: High fatigue resistance

-

5052: Excellent corrosion resistance

Industry Applications

| Industry | Typical Components | Key Benefit |

|---|---|---|

| Aerospace | Structural frames, Brackets | Weight reduction |

| Automotive | Engine parts, Housings | Heat dissipation |

| Robotics | Actuator components | Precision movement |

| Medical | Equipment housings | Sterilizable surfaces |

Quality Assurance Process

Comprehensive Inspection Protocol:

-

Material certification verification

-

First-article 3D scanning (CMM)

-

In-process dimensional checks

-

Surface finish analysis

-

Functional performance testing

Certifications:

-

ISO 9001:2015 compliant

-

AS9100 aerospace standards

-

Full material traceability

-

RoHS compliance documentation

Surface Treatment Options

Functional Finishes:

-

Hard anodizing (Type II/III)

-

Chemical film conversion coating

-

Electroless nickel plating

-

Powder coating

Aesthetic Finishes:

-

Color anodizing (multiple options)

-

Mirror polishing (Ra 0.4μm)

-

Bead blasting (uniform matte)

-

Laser engraving for markings

Why Partner With Us?

✅ 20+ years precision machining experience

✅ Prototype to production services

✅ Engineering support from design to delivery

✅ Competitive pricing with low MOQs

✅ Fast turnaround (15-day standard)

Start Your Project Today:

Submit your CAD files for:

-

Free manufacturability analysis

-

Material selection guidance

-

Competitive quotation

-

Production timeline

Our CNC milling specialists combine advanced technology with material expertise to deliver high-quality aluminum components that meet your exact specifications. Contact us to discuss your project requirements

Packing&Shipping

FAQ

Q1: What file formats do you accept for CNC rails quotes?

A1: Preferred formats: STEP, IGES, DXF. 2D drawings in PDF/DWG acceptable.

Q2: Can you produce hardened steel CNC rails?

A2: Yes, we offer through-hardened and case-hardened options up to HRC 60.

Q3: What's your standard lead time for 100 sets of 2m rails?

A3: Typically 15 working days including surface treatment.

Q4: Do you provide installation guidance?

A4: Yes, we offer technical drawings with mounting references and can provide assembly instructions.