Customized Supply CNC Lathe Machining 5 Axis CNC Parts General Parts China Trustworthy

enquiry- Specifications

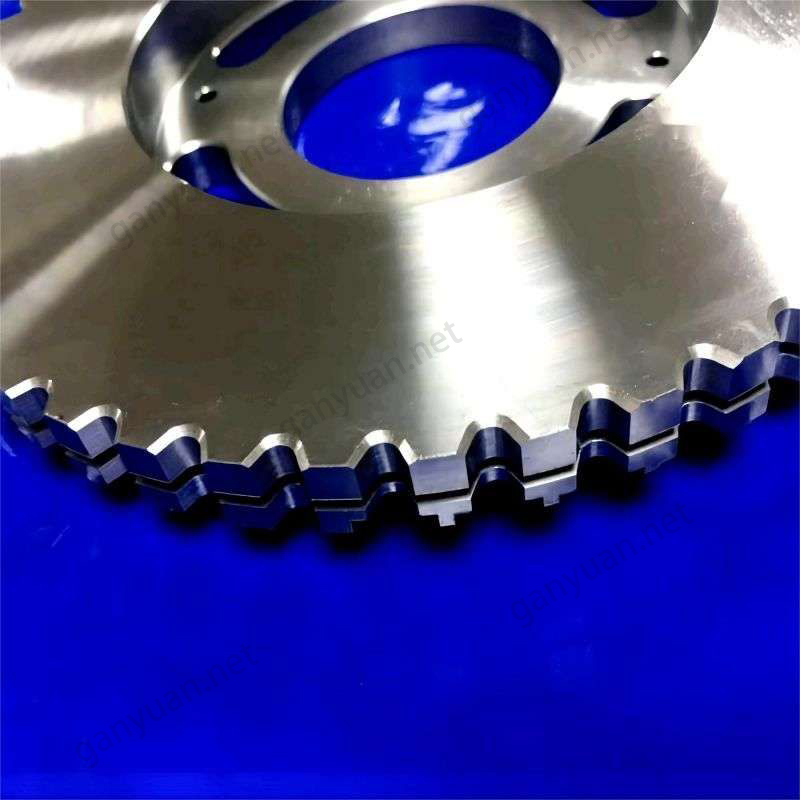

Dongguan Ganyuan Hardware Technology Co., Ltd. specializes in manufacturing precision CNC-machined impeller fans that deliver exceptional performance and durability. Our advanced five-axis machining technology ensures that each impeller fan is crafted with meticulous attention to detail, guaranteeing optimal aerodynamic efficiency and long-lasting reliability.Spare Parts CNC Parts

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,CNC Parts |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC part; Machining parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Why Choose Our CNC Parts ?

1. Unmatched Precision Engineering

Our CNC parts are manufactured using advanced 5-axis and 4-axis CNC machining centers, delivering exceptional accuracy within ±0.005mm tolerances. Every component undergoes:CNC Parts

-

3D/2D dimensional verification

-

Surface finish analysis (Ra 0.2μm achievable)

-

Customized Supply CNC Lathe Machining 5 Axis CNC Parts General Parts China

Functional testing for real-world performance

2. Advanced Manufacturing Capabilities

With 20+ years of CNC machining expertise, we specialize in:

-

Precision gear manufacturing – Optimized tooth profiles for smooth operation

-

Complex geometries – Undercuts, thin walls, and micro-features

-

Multi-material expertise – From aerospace alloys to engineering plastics

Material Options Include:

| Metals | Plastics | Special Alloys |

|---|---|---|

| Aluminum 6061/7075 | PEEK | Titanium Grade 5 |

| Stainless Steel 303/304/316 | POM | Inconel |

| Brass/Bronze | Nylon | Magnesium |

3. Rapid Production & Flexible Solutions

-

7-10 day standard lead time for most orders

-

Prototype to mass production services

-

MOQ from 1 piece for development projects

4. Comprehensive Surface Finishing

Enhance functionality and appearance with our finishing options:

Functional Treatments

▸ Hard anodizing (up to 50μm)

▸ Electroless nickel plating

▸ Heat treatment (HRC 58-62)

Aesthetic Finishes

▸ Mirror polishing (Ra 0.05μm)

▸ Custom powder coating

▸ Laser engraving for permanent markings

Our CNC Parts Manufacturing Excellence

State-of-the-Art Production Facility

-

2,000㎡ modern factory in Dongguan, China

-

ISO 9001 certified quality management

-

Automated inspection systems for consistent quality

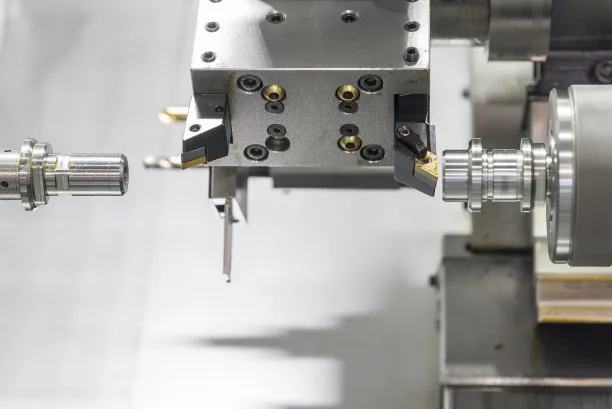

Precision Machining Equipment

-

5-axis CNC milling centers (DMG Mori, Mazak)

-

Swiss-type CNC lathes for micro-machining

-

EDM/Wire cutting machines for complex shapes

Rigorous Quality Assurance

-

First-article inspection reports

-

Material certification with full traceability

-

Statistical process control monitoring

Custom CNC Parts Solutions

We provide complete manufacturing services for:

✔ Automotive components

✔ Aerospace fittings

✔ Medical device parts

✔ Robotics mechanisms

✔ Industrial machinery parts

Design Support Services:

-

DFM analysis to optimize your designs

-

CAD/CAM programming for complex parts

-

Rapid prototyping with 3D printing options

Why Global Clients Trust Us:

-

40% cost savings vs. Western manufacturers

-

Engineering support team available 24/7

-

Door-to-door shipping with customs documentation

Contact us today for competitive quotations and technical consultations on your CNC parts requirements. Our engineering team is ready to transform your designs into high-performance precision components.