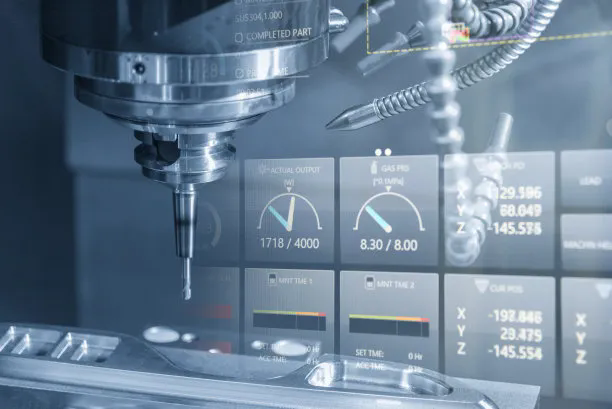

Customized Exclusive CNC machining fine-tuning disc spare parts 5axes

enquiry- Specifications

Our fine-tuning discs are crafted with high precision. With excellent durability and smooth operation, they provide the perfect solution for delicate calibration tasks.

Product Description

| Production type | Custom production and processing | Material | Metal,plastic machining, carbon steel, stainless steel, copper, aluminum alloy,plastic machining |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting fine-tuning disc |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;fine-tuning disc;Aluminum Alloy Parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Fine-Tuning Disc: Precision Calibration Components for Critical Applications

High-Accuracy Adjustment Discs for Precision Instrumentation

Why Choose Our Fine-Tuning Discs?

We manufacture precision calibration discs that deliver:fine-tuning disc

Customized Exclusive CNC machining fine-tuning disc spare parts fine-tuning-disc

✔ Micron-level accuracy (±0.005mm tolerance)

✔ Durable materials for long service life

✔ Smooth operation for precise adjustments

✔ Custom configurations for specialized equipment

Key Features:

-

Precision-ground surfaces for consistent performance

-

Balanced rotation for vibration-free operation

-

Wear-resistant materials

-

Custom graduation markings available

Manufacturing Excellence

Advanced Production Process:

-

CNC turning for base profile

-

Precision 5-axis milling for adjustment features

-

Surface grinding for flatness

-

Laser etching for precise markings

-

Dynamic balancing testing

Material Options:

-

Stainless Steel 304/316: Corrosion resistant

-

Tool Steel: High-wear applications

-

Aluminum 6061/7075: Lightweight solutions

-

Bronze: Low-friction applications

Industry Applications

| Industry | Application | Key Benefit |

|---|---|---|

| Optical | Lens calibration | Sub-micron precision |

| Medical | Surgical equipment | Sterilizable surfaces |

| Aerospace | Instrument adjustment | Temperature stable |

| Laboratory | Measurement devices | Consistent performance |

Quality Assurance

Rigorous Inspection Protocol:

-

Roundness testing (<0.001mm)

-

Surface flatness verification

-

Hardness testing

-

Material certification

-

Functional rotation testing

Certifications:

-

ISO 9001:2015 compliant

-

Measurement traceability

-

Full documentation package

-

RoHS compliance

Surface Treatment Options

Functional Finishes:

-

Electropolishing for smooth operation

-

Hard chrome plating for wear resistance

-

Black oxide for reduced glare

-

Passivation for corrosion protection

Specialty Treatments:

-

Custom laser-etched scales

-

Anti-reflective coatings

-

Conductive coatings

-

Custom color anodizing

Technical Specifications

| Parameter | Specification |

|---|---|

| Diameter Range | 10-300mm |

| Thickness Tolerance | ±0.005mm |

| Surface Finish | Ra 0.2-0.8μm |

| Maximum RPM | 5,000 |

| Temperature Range | -40°C to 150°C |

Why Partner With Ganyuan?

✅ 20+ years precision component experience

✅ Medical and aerospace-grade manufacturing

✅ Prototype to production services

✅ Competitive pricing with low MOQs

✅ Complete technical support

Start Your Project:

Submit your requirements for:

-

Free design consultation

-

Material recommendations

-

Competitive quotation

-

Prototype timeline

Our engineering team specializes in precision fine-tuning discs for critical calibration applications. Contact us today to discuss your specific needs.