Trustworthy Anti-slip knurled shaft stainless 5axes steel precision ground

enquiry- Specifications

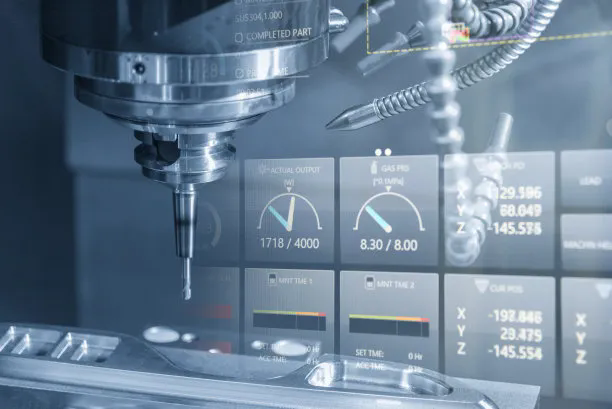

Dongguan Ganyuan Hardware Technology Co.knurled shaft, Ltd. specializes in manufacturing precision CNC-machined impeller fans that deliver exceptional performance and durability. Our advanced five-axis machining technology ensures that each impeller fan is crafted with meticulous attention to detail, guaranteeing optimal aerodynamic efficiency and long-lasting reliability.knurled shaft

Product Description

| Production type | Custom production and processing | Material | Metal,plastic machining, carbon steel, stainless steel, copper, Aluminum CNC parts,plastic machining |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing EquipmentCustom Precision CNC Parts | 5 Axis CNC Machining, grinder, CNC Machined Parts knurled shaft |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;Precision Aluminum Parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Knurled Shaft: Precision Machined Grip Components for Industrial Applications

High-Performance Knurled Shaft Manufacturing Solutions

Our Knurled Shaft Production Process

We combine advanced machining with precision finishing for superior grip components:knurled shaft

Anti-slip knurled shaft stainless steel precision ground part knurled shaft

✔ CNC turning for precise shaft dimensions

✔ 5-axis knurling for consistent grip patterns

✔ Electroplating for enhanced durability

✔ Quality inspection at every stage

Key Specifications:

-

Materials: Stainless steel, brass, aluminum, carbon steel knurled shaft

-

Tolerances: ±0.02mm standard (±0.01mm available)

-

Knurl Patterns: Diamond, straight, or custom

-

Surface Finishes: Electroplated, anodized, or polished

Knurled Shaft Applications

Featured Components:

-

Mask Machine Knurling Wheels

-

Material: 304 Stainless Steel

-

Process: CNC turning → 5-axis knurling → Nickel plating

-

Feature: Non-slip medical-grade surface

-

-

Motor Shaft Copper Sleeves

-

Material: H59 Brass

-

Process: Precision turning → Knurling → Electroplating

-

Benefit: Excellent wear resistance knurled shaft

-

-

Fine-Tuning Dials

-

Material: Carbon Steel

-

Process: CNC lathe → Precision knurling → Chrome plating

-

Application: Equipment calibration controls

-

Material Options

| Material | Advantages | Common Uses |

|---|---|---|

| 303 Stainless | Corrosion resistant | Medical devices |

| H59 Brass | Excellent machinability | Bushings, sleeves |

| AL6061 | Lightweight | Robotics components |

| 1045 Steel | High strength | Industrial controls |

Manufacturing Capabilities

Precision Equipment:

-

CNC turning centers (Ø5mm-Ø150mm)

-

5-axis machining for complex knurl patterns

-

Automated finishing systems

-

Precision measurement tools

Quality Assurance:

-

100% dimensional verification

-

Surface roughness testing

-

Material certification

-

Functional testing

Surface Treatment Options

Functional Finishes:

-

Electroless nickel plating

-

Hard chrome plating

-

Passivation (stainless steel)

-

Anodizing (aluminum)

Aesthetic Finishes:

-

Mirror polishing

-

Satin finishing

-

Custom color anodizing

-

Laser marking

Why Choose Our Knurled Shafts?

✅ 20+ years precision machining experience

✅ Custom knurl patterns to your specifications

✅ Material expertise for optimal performance

✅ Competitive pricing with low MOQs

✅ Fast turnaround (10-15 day standard)

Start Your Project:

Submit your shaft requirements for:

-

Free design consultation

-

Material recommendations

-

Competitive quotation

-

Prototype timeline

Our engineering team specializes in creating precision knurled components that combine perfect grip with lasting durability. Contact us today to discuss your knurled shaft needs.knurled shaft

-

FAD

Q1: Where can I get product & price information?A1: Send us an inquiry e-mail, we will contact you once we received your mail.Q2: How long will I get the sample?A2: Depends on your specific items, within 3-7 days generally.Q3: What kinds of information do you need for a quote?A3: Kindly please provide the product drawings in PDF, if provide in STEP or IGS will be better.Q4: What are the payment terms?A4: We accept 50% as a payment deposit, when the goods are prepared, we shoot photos or videos for your check, and then you can pay the balance. For small quantities, we accept Paypal, the commission will be added to the order. For big amounts, T/T is preferred.Q5: How to deliver the goods?A5: We deliver the products by courier company.Q6: Are you a trading company or factory?A6: We are factory direct with 17 experienced engineers and more than 50 employees as well approximate 3,000m2 workshop area.Q7: What shall we do if we don't have drawings?A7: Please send your sample to our factory, then we can copy and provide you better solutions. If send us pictures or drafts with dimensions(Length, Height, Width), CAD or 3D file will be made for you.Q8: Can we get some samples before mass production?A8: Absolutely yes.Q9: Will my drawings be safe after sending them to you?A9: Yes, we will keep them well and won't release them to the third party without your permission.Q10: Is it possible to know the operation status of my products without visiting your company?A10: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.Q11: If you make poor quality goods, will you refund?A11: In fact, we won't take risks to produce poor-quality products. Meanwhile, we manufacture good quality products till you are satisfied plastic machining.