Trustworthy Custom-made 5-axis lathe parts made of high-precision stainless steel

enquiry- Specifications

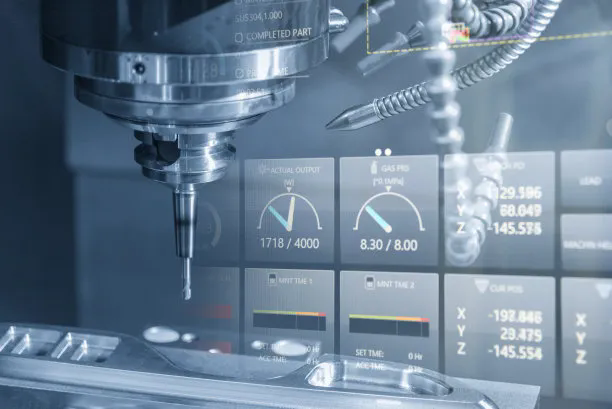

Lathe Parts delivers precision cuts and high-quality finishes. Ideal for custom metal components, ensuring perfect fit.

Product Description

| Production type | Custom production and processing | Material | Metal,plastic machining, carbon steel, stainless steel, copper, aluminum alloy,cnc machining metal parts |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting lathe parts |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts;Lathe Parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Lathe Parts: Precision CNC-Turned Components for Automotive Excellence

Advanced Machining Solutions for Critical Automotive Applications

Why Choose Our Lathe Parts Manufacturing?

We deliver precision automotive components with industry-leading capabilities:lathe parts

Custom-made 5-axis lathe parts made of high-precision stainless steel lathe parts

✔ Ultra-tight tolerances (±0.02mm standard)

✔ Multi-material expertise from aluminum to titanium

✔ Superior surface finishes (Ra 0.4-0.8μm achievable)

✔ Rapid 15-day turnaround for production orders

✔ Low MOQ flexibility (from 10 pieces)

Key Automotive Components:

-

Engine systems: Crankshafts, camshafts, valve seats

-

Drivetrain: Transmission gears, drive shafts, splines

-

Suspension: Bushings, bearings, steering components

-

Braking: Caliper pistons, rotor hubs lathe parts

State-of-the-Art Manufacturing Capabilities

Precision Equipment Portfolio:

-

Multi-axis CNC lathes with live tooling

-

Swiss-type turning centers for micro-precision

-

Y-axis machining for complex geometries

-

Automated bar feeders for high-volume production

Material Specializations:

-

Aluminum Alloys: 6061-T6, 7075-T6

-

Stainless Steels: 303, 304, 416

-

Carbon Steels: 1045, 4140, 4340

-

Exotic Metals: Titanium, Inconel

Quality Assurance Process

Comprehensive Inspection Protocol:

-

Material certification verification

-

First-article 3D scanning (CMM)

-

In-process dimensional validation

-

Surface roughness analysis

-

Functional performance testing

Certifications & Standards:

-

IATF 16949:2016 compliant

-

PPAP documentation available

-

Full material traceability

-

RoHS/REACH compliance

Surface Enhancement Options

Functional Treatments:

-

Hard anodizing (for aluminum components)

-

Electroless nickel plating

-

Nitriding for wear resistance

-

Passivation for corrosion protection

Aesthetic Finishes:

-

Mirror polishing (Ra 0.2μm)

-

Bead blasting (uniform matte)

-

Custom powder coating

-

Laser engraving for markings

Technical Specifications

| Parameter | Capability |

|---|---|

| Diameter Range | 2mm-300mm |

| Length Capacity | Up to 600mm |

| Tolerance Standard | ±0.02mm (±0.01mm available) |

| Surface Finish | Ra 0.4-3.2μm |

| Maximum RPM | 8,000 |

Why Partner With Us?

✅ 20+ years automotive machining expertise

✅ Complete prototyping to production services

✅ Engineering support from design to delivery

✅ Competitive global pricing

✅ Strict confidentiality protocols

Start Your Project Today:

Submit your CAD files for:

-

Free manufacturability analysis

-

Material selection consultation

-

Competitive quotation

-

Prototype timeline

Our lathe specialists combine advanced CNC technology with automotive manufacturing expertise to deliver precision components that exceed industry standards. Contact us to discuss your project requirements.