Reliable 4 axis reciprocating shaft cam double head screw shaft

enquiry- Specifications

Searching for a reliable reciprocating shaft? Ours are precision - engineered, ensuring smooth linear - to - rotary motion conversion for enhanced machinery performance.reciprocating shaft

OEM cnc turned steel parts are made by lathe. The material is carbon steel and the surface is satin polished. For CNC turning steel lathe parts, the minimum order quantity is 10 pieces and the delivery time is 15 days. The critical tolerance of CNC turned steel spare parts is +/-0.02MM and the surface roughness is Ra 0.8. ganyuan has rich experience in producing such OEM cnc turned steel spare parts, we have more than 100 different types of lathes. If you have any questions about OEM cnc turning steel lathe parts, please feel free to contact us.

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

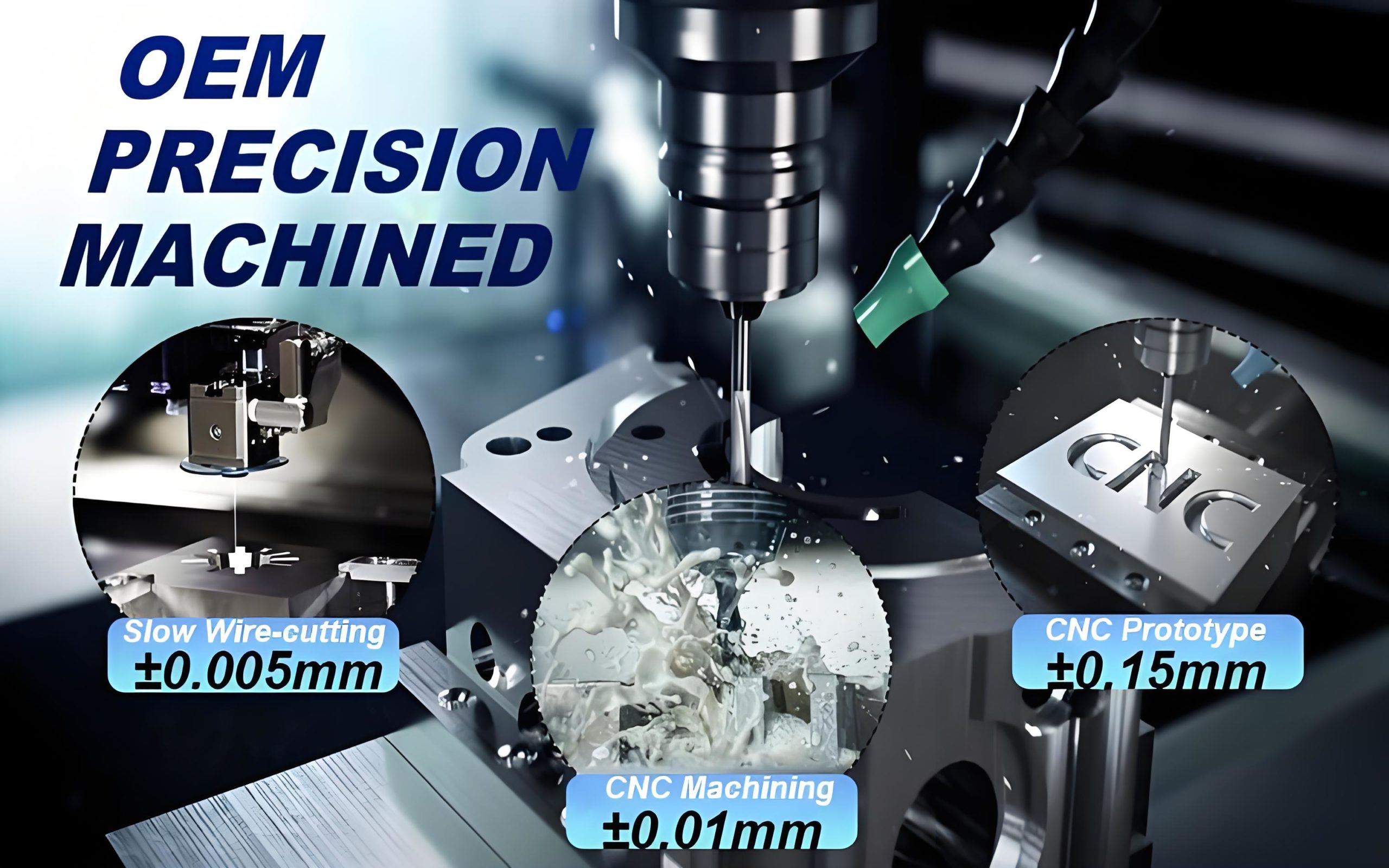

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,cnc machined components |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;reciprocating shaft |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Reciprocating Shaft: Precision Engineered for Optimal Motion Conversion

High-Performance Reciprocating Shafts for Industrial Applications

Why Choose Our Reciprocating Shafts?

We manufacture precision reciprocating shafts that deliver:

Reliable 4 axis reciprocating shaft cam double head screw shaft

✔ Smooth linear-to-rotary motion conversion

✔ Exceptional durability for demanding cycles

✔ Precision tolerances (±0.01mm achievable)

✔ Custom configurations for specific applications

Key Features:

-

Optimized for minimal vibration

-

Precision-ground bearing surfaces

-

Wear-resistant materials

-

Balanced for high-speed operation

Manufacturing Excellence

Advanced Production Process:

-

CNC turning for precise diameters

-

Precision grinding for critical surfaces

-

Heat treatment for enhanced durability

-

Dynamic balancing testing

-

Surface finishing for performance

Material Options:

-

4140 Alloy Steel (standard)

-

Stainless Steel 304/316 (corrosion resistant)

-

Tool Steel (high wear applications)

-

Custom Alloys available

Quality Assurance

Rigorous Inspection Protocol:

-

Dimensional verification (CMM)

-

Surface hardness testing

-

Runout and straightness measurement

-

Material certification

-

Functional performance testing

Surface Treatment Options

Functional Finishes:

-

Hard chrome plating

-

Nitriding for wear resistance

-

Induction hardening

-

Precision polishing

Specialty Treatments:

-

Black oxide coating

-

Electroless nickel plating

-

Laser etching for identification

-

Custom protective coatings

Why Choose Ganyuan?

✅ 20+ years precision shaft manufacturing

✅ Custom engineering support

✅ Prototype to production services

✅ Competitive pricing with low MOQs

✅ Fast turnaround (15-day standard)

Start Your Project:

Submit your requirements for:

-

Free design consultation

-

Material recommendations

-

Competitive quotation

-

Prototype timeline

Our engineering team specializes in high-performance reciprocating shafts for critical motion applications. Contact us today to discuss your specific needs.

Packing&Shipping