Stable quality and durable drive shaft machining through 4-axis CNC precision processing

enquiry- Specifications

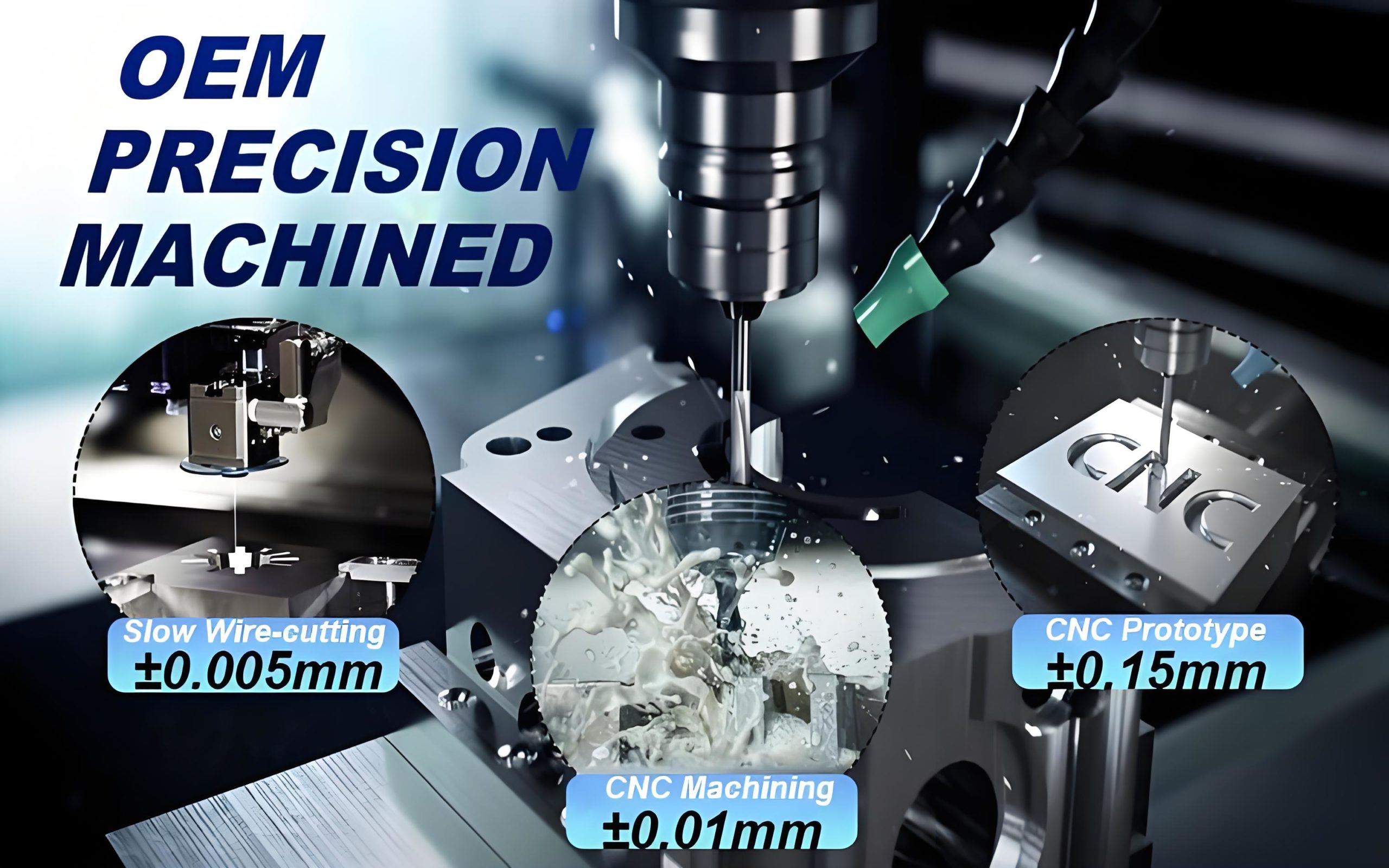

At Dongguan Ganyuan Hardware Technology Co., Ltd., we specialize in high-tolerance shaft machining, delivering stainless steel shafts that excel in strength, corrosion resistance, and precision. Our CNC shaft machining capabilities produce components with ±0.02mm tolerances, ensuring flawless integration into critical systems across industries.shaft machining

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,cnc machined components |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;Custom shaft machining |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Why Choose Our Shaft Machining Services?

✔ Advanced CNC Machining

- 5-axis CNC milling/turning for complex geometries

- Precision grinding for surface finishes down to Ra 0.2μm

- Swiss-type lathes for micro-diameter shafts (Ø1mm–30mm)

Stable quality and durable drive shaft machining through CNC precision processing

✔ Material Expertise

- Stainless Steel (303/304/316L): Ideal for corrosive environments

- Alloy Steel (4140/4340): Heat-treated for heavy-load applications

- Titanium (Grade 5/23): Lightweight yet ultra-strong

✔ Enhanced Performance Treatments

- Hard Chrome Plating: Wear resistance up to HRC 70

- Plasma Nitriding: For shafts exposed to extreme friction

- Electropolishing: FDA-compliant finishes for food/medical use

✔ Customization Options

- Diameters: 1mm–300mm

- Lengths: Up to 2,000mm (special sizes available)

- Features: Keyways, splines, threads, flanges

Materials & Surface Treatments

Premium Materials for Superior Performance

We source high-grade materials, including:

-

Stainless Steel (303/304/316) – Corrosion-resistant for medical & marine applications

-

Aluminum Alloys (6061/7075) – Lightweight yet durable for aerospace & robotics

-

Carbon Steel (1045/4140) – High-strength for automotive & industrial use

-

Titanium & Brass – Specialized applications requiring high fatigue resistance

Custom Surface Finishing

Enhance performance and longevity with:

-

Anodizing & Hard Anodizing – Improved wear resistance

-

Electroplating (Ni, Zn, Cr, TiCN) – Enhanced corrosion protection

-

Heat Treatment & Nitriding – Increased hardness & durability

-

Polishing & Sandblasting – Superior surface smoothness

Why Choose Our Shaft Machining Services?

✅ 20+ Years of Expertise – Proven track record in precision manufacturing

✅ Advanced CNC Machining – High accuracy & repeatability

✅ Strict Quality Assurance – Full compliance with industry standards

✅ Custom Solutions – Tailored to your exact specifications

✅ Competitive Pricing & Fast Lead Times – Cost-effective without compromising quality

Reliable Packaging & Global Shipping

We ensure safe delivery of stainless steel shafts with customized packaging:

-

Commercial Packaging – Individual plastic bags + cartons + pallets.

-

Industrial Packaging – Protective tubes + kraft paper + wooden crates.

-

Customer-Specified Packaging – Tailored to your logistics needs.

Partner with Us for Premium shaft machining

At Dongguan Ganyuan Hardware Technology Co., Ltd., we combine advanced manufacturing, rigorous quality control, and innovative R&D to produce stainless steel shafts that exceed industry standards. Whether you need standard or custom-engineered solutions, our team is ready to meet your requirements.

FAQ

Q1: What file formats do you accept for needle wheel ratchet quotes?

A1: Preferred formats: STEP, IGES, Parasolid. 2D drawings in PDF/DWG acceptable.

Q2: Can you produce miniature needle wheel ratchets (<10mm diameter)?

A2: Yes, our Swiss CNC machines specialize in micro-components down to 2mm.

Q3: What's your standard lead time for 500pcs order?

A3: Typically 12 working days including surface treatment.

Q4: Do you provide corrosion testing reports?

A4: Yes, salt spray testing reports available upon request.

Q5: How to deliver the goods?