High-quality 5-axis industrial spare parts with stable quality, durability and high quality

enquiry- Specifications

Dongguan Ganyuan Hardware Technology Co., Ltd. specializes in manufacturing precision CNC-machined impeller fans that deliver exceptional performance and durability. Our advanced five-axis machining technology ensures that each impeller fan is crafted with meticulous attention to detail, guaranteeing optimal aerodynamic efficiency and long-lasting reliability.Spare Parts

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

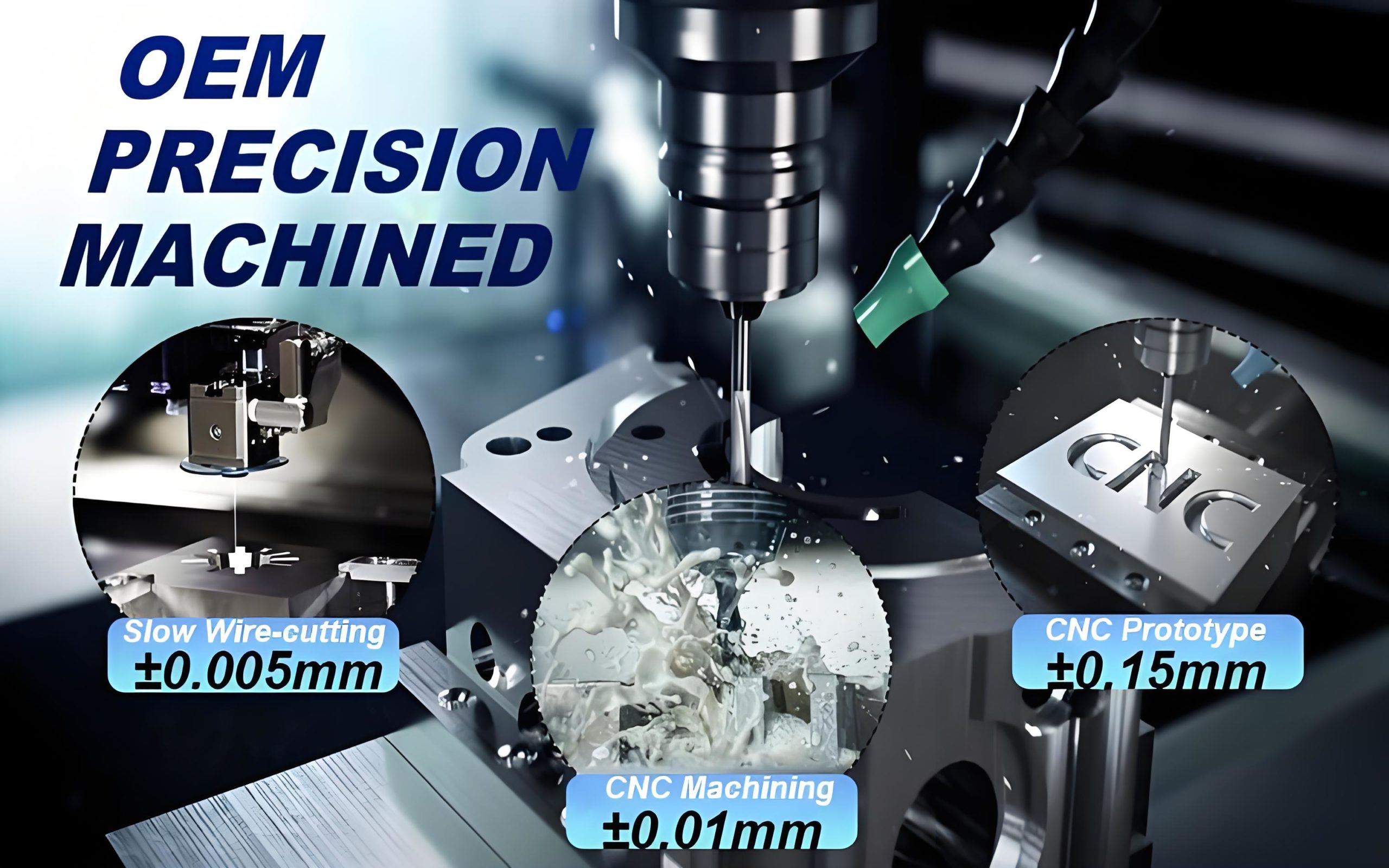

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cuttingSpare Parts |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts;CNC machining parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Premium Aluminum Spare Parts for Various Industries

High-quality 5-axis industrial spare parts with stable quality, durability and high quality

Our company specializes in manufacturing high-performance aluminum spare parts, primarily using 6061 and 7075 aluminum alloys. These materials offer excellent corrosion resistance, oxidation resistance, and long-term durability, making them ideal for demanding applications across multiple industries.

With advanced CNC machining capabilities, we produce precision spare parts that meet strict quality standards. Our products are widely used in:

-

Aerospace

-

Automotive manufacturing

-

Consumer electronics

-

Industrial machinery

Aluminum spare parts provide an optimal balance of lightweight properties, strength, and toughness, ensuring reliable performance in critical applications.

Auxiliary Processing & Surface Treatment:

-

Anodizing (including hard anodizing)

-

Electroplating

-

Powder coating, spray painting, sandblasting

-

Heat treatment, hardening, laser marking

Quality Assurance & Testing:

-

3D & 2D measuring systems

-

Hardness testers, height meters, projectors

-

Strict quality control protocols

We collaborate with high-quality material suppliers to ensure superior performance and durability for all ourSpare Parts

Why Choose Our Aluminum Spare Parts?

Superior Material Selection

We work with certified suppliers to provide:

-

Aluminum alloys (6061, 6063, 7075)

-

Stainless steel (303, 304, 316)

-

Carbon steel, copper, brass, titanium

-

Engineering plastics (POM, PEEK, PA, etc.)

Precision Machining Capabilities

-

CNC turning & milling

-

Multi-axis machining for complex geometries

-

Tight tolerance control (±0.005mm)

-

Company Profile:Trusted Manufacturer of Aluminum Spare Parts

-

We are a leading manufacturer and supplier based in Dongguan City, Guangdong Province, China, with over 20 years of experience in precision machining. Our factory spans 2,000 square meters and is equipped with state-of-the-art production technology, including:

Core Production Equipment:

- CNC lathes

- 5-axis & 4-axis CNC machines

- Stamping & die-casting equipment

Custom Surface Finishing

We offer a variety of surface treatments to enhance durability and aesthetics:

-

Anodizing (color, hard coat)

-

Plating (nickel, zinc, chrome, gold, silver)

-

Powder coating, polishing, passivation

Reliable Supply & Competitive Pricing

-

Fast lead times

-

Bulk order discounts

-

OEM/ODM support

Industries We Serve

Our aluminum spare parts are trusted by leading companies in:

✔ Aerospace – Lightweight, high-strength components

✔ Automotive – Durable engine & chassis parts

✔ Electronics – Precision housings & connectors

✔ Industrial Machinery – Wear-resistant replacements

Packing&Shipping