Reliable high-strength and wear-resistant TC4 titanium alloy precision CNC turned parts

enquiry- Specifications

Titanium alloy stands out as one of the most advanced engineering materials, offering unmatched durability, exceptional heat resistance, and remarkable versatility across industries. Whether in aerospace, medical devices, automotive engineering, or high-performance consumer products, titanium alloy delivers superior performance where strength, lightweight properties, titanium alloy and corrosion resistance are critical.

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

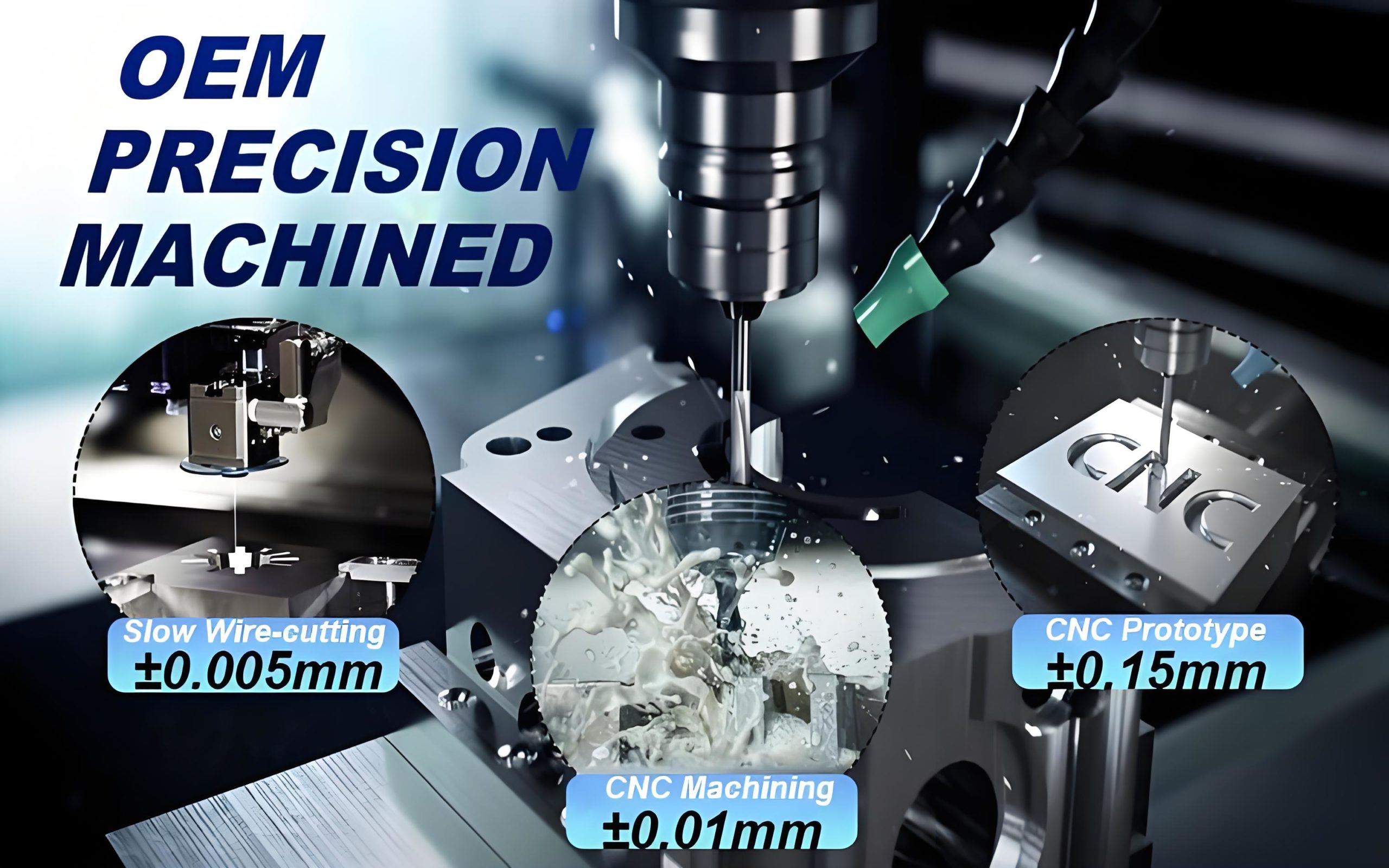

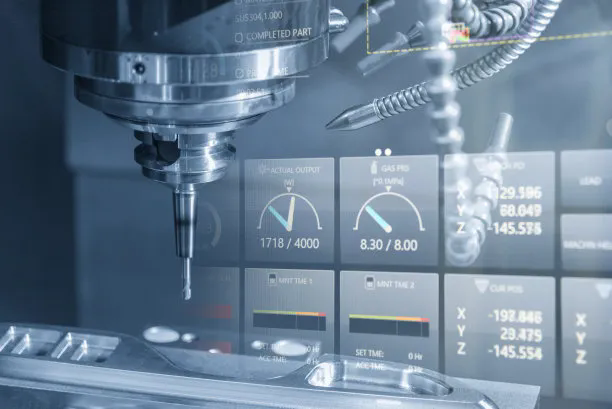

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting, titanium alloy |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts; titanium alloy TC4 |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Titanium fasteners: the perfect combination of light weight and high strength

Titanium alloy fasteners are the first choice for aerospace, medical and high-end industrial sectors due to their excellent strength-to-weight ratio and excellent corrosion resistance. The following are the core advantages and application scenarios of titanium alloy fasteners.

Reliable high-strength and wear-resistant TC4 titanium alloy precision CNC turned parts

The core advantages of titanium alloy fasteners

1. Unmatched strength-to-weight ratio

Titanium fasteners are 60% lighter than steel fasteners, but have the same or even higher strength than high-grade steel. This feature makes it ideal for:

-

Aerospace: Aircraft structural fasteners, engine bolts, landing gear connectors

-

Medical implants: orthopedic screws, dental implant fixings

-

High-performance sports equipment: racing bolts, high-end bicycle components

By reducing weight without sacrificing strength, titanium fasteners significantly improve fuel efficiency, athletic performance, and long-term reliability for medical implants.

2. Excellent high temperature and corrosion resistance

Titanium alloy fasteners can maintain stable performance in extreme environments, suitable for:

-

Aero engines: high-temperature bolts and turbine blade fixings

-

Chemical equipment: reactor fasteners that resist acid and alkali corrosion

-

Offshore engineering: seawater corrosion-resistant ship-offshore platform connectors

The naturally occurring oxide layer on the surface of titanium alloys is resistant to corrosion and ensures long-term use in harsh environments.

Precision machining technology for titanium alloy fasteners

We specialize in high-precision CNC machining of titanium alloy TC4 (Ti-6Al-4V) fasteners, providing the following services:

1. Advanced processing technology

-

Multi-axis CNC machining: 5-axis linkage ensures precise forming of complex structures

-

Precision Turning & Milling: High tolerances (±0.01mm)

-

Customized production: support PDF, DWG, STP and other format drawings for quick quotation

2. Strict quality control

-

3D scan inspection: Make sure the dimensions fit the design exactly

-

Hardness test: Verify the mechanical properties of materials

-

Surface Integrity Check: Eliminate microcracks and defects

Surface treatment scheme for titanium alloy fasteners

To enhance performance and aesthetics, we offer a variety of surface treatment technologies:

| Treatment process | function | Applicable scenarios |

|---|---|---|

| Anodizing | Enhanced abrasion resistance and available in a variety of colors | Aviation and sports equipment |

| Electropolishing | Ultra-smooth surface for improved corrosion resistance | Medical implants, chemical equipment |

| Plating (nickel, chromium, TiCN) | Improves hardness and abrasion resistance | High-load industrial fasteners |

| Laser marking | Permanent identification for easy traceability | Aerospace, auto parts |

Why Choose Our Titanium Fasteners?

-

20 years of industry experience: deep cultivation of titanium alloy precision machining, mature and reliable technology

-

Whole-process service: one-stop solution from design optimization to mass production

-

Global delivery: Customized packaging (shockproof foam/pallet packing) to support international logistics

At the same time, we provide stainless steel, aluminum alloy and other metal fastener processing to meet diverse needs.