Trust us for turning and milling. Our meticulous process, from design to finish, guarantees parts with excellent surface quality and dimensional accuracy.Turning and Milling

Product Description

| Production type |

Custom production and processing |

Material |

Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods |

CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting |

Processing Equipment |

CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,Turning and Milling |

| Accuracy |

±0.02mm |

Whether proofing |

yes |

| Is it customized |

yes |

Proofing time |

7-15 days |

| OEM/ODM |

OEM ODM CNC machining service |

surface treatment |

Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin |

Dongguan, China |

Quotations |

FOB |

| Business Type: |

Manufacturer/Factory & Trading Company |

Main Products: |

CNC parts; Machining parts;Turning and Milling |

| Management System Certification: |

ISO 9001:2015 |

Average Lead Time: |

Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

Why Choose Our Precision Machining Services?

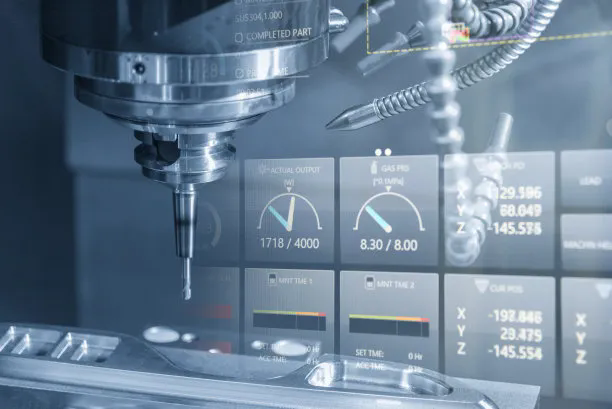

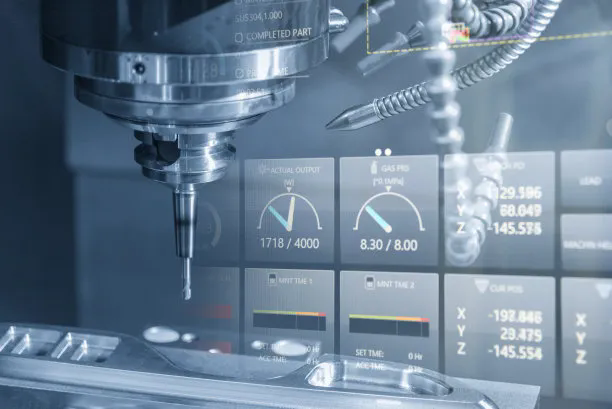

Our state-of-the-art turning and milling capabilities deliver exceptional results for critical applications:Turning and Milling

Professional Turning and Milling Composite Parts 5 Axis Precision Parts Mechanical Turning and Milling

✔ Ultra-tight tolerances (±0.015mm standard)

✔ Specialized stainless steel expertise with optimized tool paths

✔ Complex geometry machining including contours and 3D surfaces

✔ Multi-process integration for complete part fabrication

Material Capabilities:

-

Stainless Steel: 303/304/316 with superior surface finishes

-

High-Temp Alloys: Inconel, Hastelloy

-

Aluminum: 6061/7075 for lightweight applications

-

Exotics: Titanium and magnesium alloys

CNC Machining Capabilities Turning and Milling

Turning Center Features:

-

Live tooling for complete milling-turning operations

-

Sub-spindle configurations for complete part processing

-

Bar feeders for high-volume production (up to Ø65mm)

-

Y-axis capability for complex off-center features

Milling Center Features:

-

5-axis simultaneous machining

-

High-speed spindles (up to 20,000 RPM)

-

Large work envelope (800×500×500mm)

-

Automated pallet changers for continuous operation

Stainless Steel Machining Expertise

| Challenge |

Our Solution |

Benefit |

| Work hardening |

Optimized tool paths |

Consistent dimensional accuracy |

| Built-up edge |

Specialized coatings |

Improved surface finish |

| Heat management |

High-pressure coolant |

Extended tool life |

| Chip control |

Custom chip breakers |

Uninterrupted production |

Quality Assurance Protocol

Comprehensive Inspection Process:

-

First-article validation with CMM scanning

-

In-process verification of critical dimensions

-

Surface finish analysis (Ra 0.4μm achievable)

-

Full material traceability with certifications

Available Certifications:

-

ISO 9001:2015 compliant processes

-

Material test reports (MTR)

-

PPAP documentation packages

-

RoHS/REACH compliance

Company Overview

Ganyuan Manufacturing Facilities

🏭 20+ Years precision machining experience

📍 2,000m² Facility in Dongguan, China

🛠️ Equipment Highlights:

🛠️ Equipment Highlights:

-

Multi-axis turning centers with live tooling

-

5-axis milling machines

-

Swiss-type precision lathes

-

Automated measurement systems

Why Partner With Us?

✅ Medical and aerospace-grade precision

✅ Prototype to production services

✅ Strict process control at every stage

✅ Complete documentation package

Material Specifications

Metals We Machine:

-

Stainless Steel: 303, 304, 316, 17-4PH

-

Aluminum: 6061, 7075, 2024

-

Titanium: Grade 2, 5, 9

-

Copper Alloys: Brass, Bronze, Beryllium Copper

Surface Finishing Options

Functional Treatments:

-

Precision grinding (Ra 0.2μm achievable)

-

Electropolishing for corrosion resistance

-

Hard anodizing for aluminum components

-

Passivation for stainless steel

Aesthetic Finishes:

-

Mirror polishing (optical-grade finishes)

-

Bead blasting (uniform matte finish)

-

Custom powder coating (wide color selection)

Our machining experts combine advanced CNC technology with decades of experience to deliver precision turned and milled components that meet your most demanding specifications. Contact us to discuss your project requirements.

Packaging Details 1. Commercial packaging: 1pc/plastic bag + color box +carton + pallet; 2. Industrial packaging: (1). plastic tube + carton + pallet; (2). plastic bag + kraft paper + carton + pallet; 3. According to the requirement of customer.

FAQ

Q1: Where can I get product & price information?

A1: Send us an inquiry e-mail, we will contact you once we received your mail.

Q2: How long will I get the sample?

A2: Depends on your specific items, within 3-7 days generally.

Q3: What kinds of information do you need for a quote?

A3: Kindly please provide the product drawings in PDF, if provide in STEP or IGS will be better.

Q4: What are the payment terms?

A4: We accept 50% as a payment deposit, when the goods are prepared, we shoot photos or videos for your check, and then you can pay the balance. For small quantities, we accept Paypal, the commission will be added to the order. For big amounts, T/T is preferred.

Q5: How to deliver the goods?

A5: We deliver the products by courier company.

Q6: Are you a trading company or factory?

A6: We are factory direct with 17 experienced engineers and more than 50 employees as well approximate 3,000m2 workshop area.

Q7: What shall we do if we don’t have drawings?

A7: Please send your sample to our factory, then we can copy and provide you better solutions. If send us pictures or drafts with dimensions(Length, Height, Width), CAD or 3D file will be made for you.

Q8: Can we get some samples before mass production?

A8: Absolutely yes.

Q9: Will my drawings be safe after sending them to you?

A9: Yes, we will keep them well and won’t release them to the third party without your permission.

Q10: Is it possible to know the operation status of my products without visiting your company?

A10: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q11: If you make poor quality goods, will you refund?

A11: In fact, we won’t take risks to produce poor-quality products. Meanwhile, we manufacture good quality products till you are satisfied plastic machining.

Professional plastic production process 5-axis CNC precision machining, durable customization

Professional plastic production process 5-axis CNC precision machining, durable customization Reliable high-precision wheels and rollers made of 304 stainless steel

Reliable high-precision wheels and rollers made of 304 stainless steel High-precision flashlight housing1: Precisely designed with superior performance

High-precision flashlight housing1: Precisely designed with superior performance Customized Exclusive 5 axes CNC machining fine-tuning disc spare parts

Customized Exclusive 5 axes CNC machining fine-tuning disc spare parts Exquisite of 5 axes Semiconductor Accessories, Couplings and Aluminum Alloy Accessories

Exquisite of 5 axes Semiconductor Accessories, Couplings and Aluminum Alloy Accessories

🛠️ Equipment Highlights:

🛠️ Equipment Highlights: