Professional valve block CNC lathe and five-axis CNC machining 6061 Aluminum

enquiry- Specifications

Need a customized valve block? We offer tailor - made solutions to meet your specific requirements.

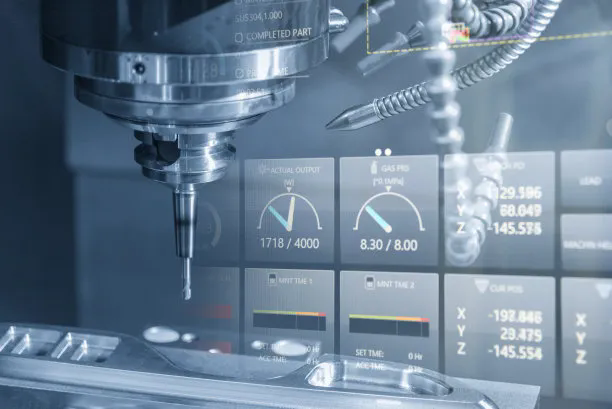

Dongguan Ganyuan Hardware Technology Co., Ltd. proudly presents our superior CNC Parts for Five-Axis Machining. Our precision-engineered CNC Machining Parts are the epitome of quality and efficiency, tailored for high-performance milling machines. Elevate your machinery with our meticulously crafted CNC Machining Components, designed to meet the highest standards of accuracy and durability. Whether you choose our state-of-the-art Five-Axis or versatile Four-Axis CNC Machining Parts, you will significantly optimize your production processes. Rely on our CNC Machined Parts for unparalleled reliability and consistent performance. Revitalize your machining system with our premium CNC Parts, specifically designed for Five-Axis Machines, ensuring excellence in every cut.valve block

Product Description

| Production type | Custom production and processing | Material | Metal, non-metal, carbon steel, stainless steel, copper, aluminum alloy |

| Processing methods | CNC Trining Parts 5-axis CNC machining centers, grinding machines, wire cutting | Processing Equipment | CNC Trining Parts 5-axis CNC machining center, grinder, wire cutting,cnc machined components |

| Accuracy | ±0.02mm | Whether proofing | yes |

| Is it customized | yes | Proofing time | 7-15 days |

| OEM/ODM | OEM ODM CNC machining service | surface treatment | Electroplating, zinc plating, chrome plating, nickel plating, oxidation, hard oxidation |

| Origin | Dongguan, China | Quotations | FOB |

| Business Type: | Manufacturer/Factory & Trading Company | Main Products: | CNC parts; Machining parts; Custom Auto Parts |

| Management System Certification: | ISO 9001:2015 | Average Lead Time: | Peak Season Lead Time: within 15 workdays Off Season Lead Time: within 15 workdays |

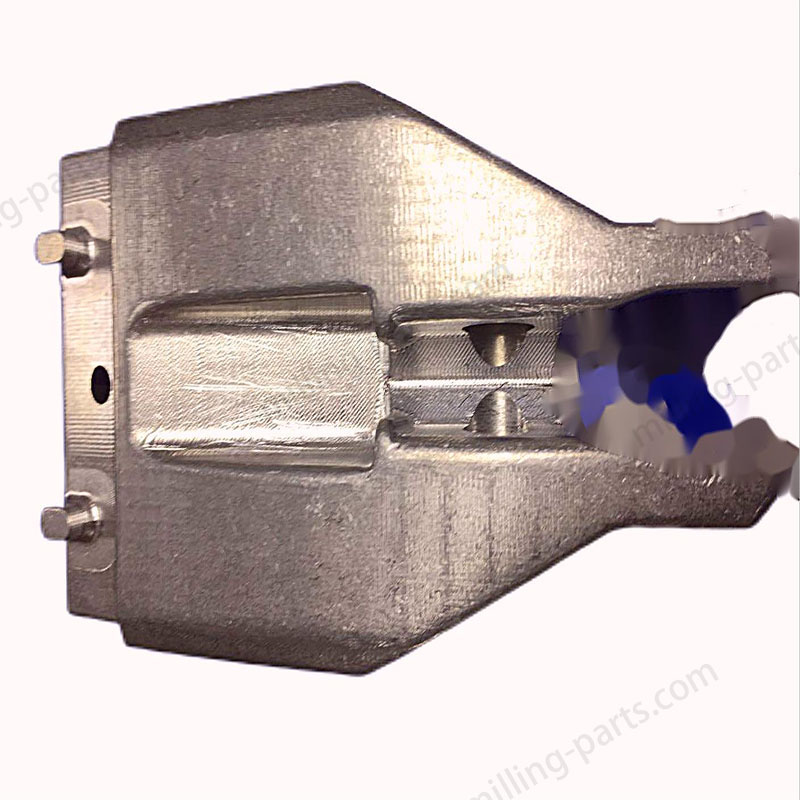

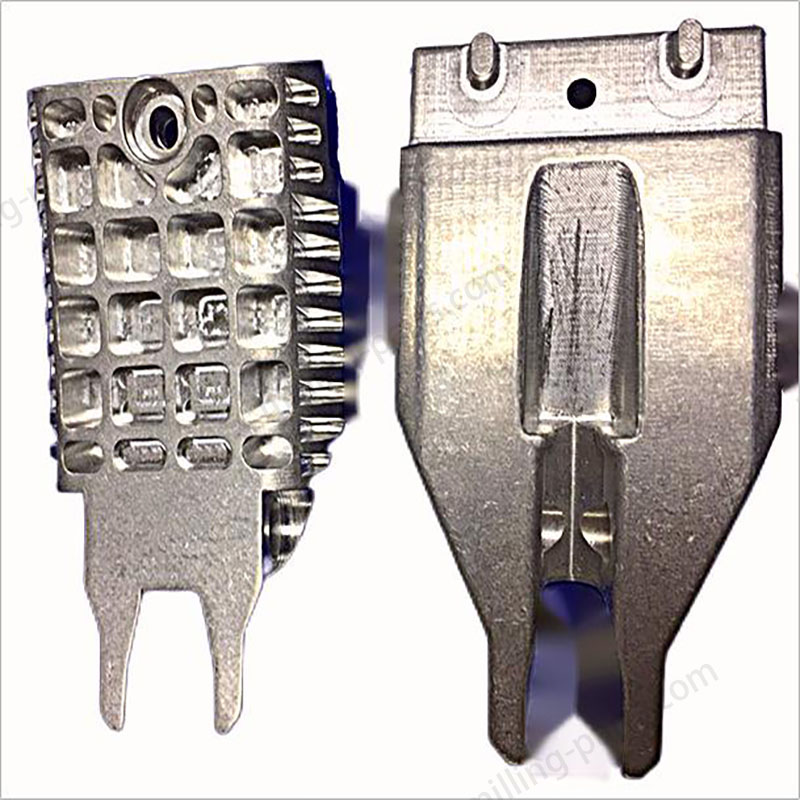

Valve Block: Precision Aluminum Alloy Machining Solutions

Custom Engineered Valve Blocks for Fluid Control Systems

Why Choose Our Valve Block Manufacturing?

We deliver high-performance valve blocks with:

Professional valve block CNC lathe and five-axis CNC machining 6061 Aluminum

✔ Precision CNC milling (±0.02mm tolerances)

✔ Material expertise (6061/7075 aluminum alloys)

✔ Complex internal channel machining

✔ Multiple surface treatment options

Key Features:

-

Leak-proof precision fluid passages

-

Optimized flow characteristics

-

High pressure/vacuum compatibility

-

Custom port configurations

Advanced Manufacturing Capabilities

5-Axis CNC Machining Process:

-

Precision milling of block geometry

-

Deep hole drilling for fluid channels

-

Thread machining for port connections

-

Surface finishing for performance

Material Options:

-

6061-T6 Aluminum (standard)

-

7075-T6 Aluminum (high strength)

-

2024 Aluminum (aerospace grade)

-

Stainless Steel (304/316 for corrosive environments)

Quality Assurance Protocol

Comprehensive Testing:

-

Dimensional verification (CMM)

-

Pressure testing (up to 10,000 PSI)

-

Surface roughness measurement

-

Material certification

-

Functional flow testing

Surface Treatment Options

Functional Finishes:

-

Hard anodizing (Type III)

-

Electroless nickel plating

-

Chemical film conversion

-

Passivation (for stainless steel)

Aesthetic Finishes:

-

Color anodizing (multiple options)

-

Bead blasting (uniform matte)

-

Laser marking for identification

-

Custom powder coating

Technical Specifications

| Parameter | Capability |

|---|---|

| Size Range | 10-500mm |

| Tolerance | ±0.02mm (±0.01mm available) |

| Pressure Rating | Up to 10,000 PSI |

| Surface Finish | Ra 0.8-3.2μm |

| Lead Time | 15 days standard |

Why Partner With Us?

✅ 20+ years fluid system component experience

✅ Prototype to production services

✅ Engineering support for optimal design

✅ Competitive pricing with low MOQ

✅ Complete documentation package

Start Your Valve Block Project:

Submit your CAD files (PDF/DWG/STP/IGS) for:

-

Free manufacturability review

-

Material recommendations

-

Competitive quotation

-

Production timeline

Our engineering team specializes in precision-machined valve blocks for critical fluid control applications. Contact us today to discuss your requirements.

Packing&Shipping